- Industrial machines and equipment

- Mixing and Dosing

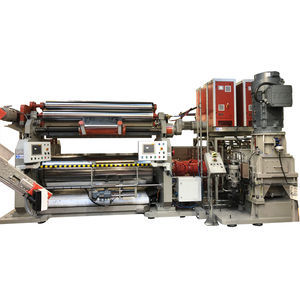

- Twin-screw mixer

- Lescuyer Villeneuve

Twin-screw mixer continuousfor liquidsconical

Add to favorites

Compare this product

Characteristics

- Technology

- twin-screw

- Batch/continuous

- continuous

- Product type

- for liquids

- Other characteristics

- conical, modular

Description

This tool fed by large batches is used in the medium-sized processing industry but also in R&D. The Lescuyer conical twin-screw mixer is placed following an internal mixer to immediately shape the material.

In production, it increases the productivity by allowing the process to be continuous.

The project was developed as part of a national innovation project, and therefore has high-level instrumentations, ease of cleaning and maintenance superior to usual equipment.

This Lescuyer equipment meets the highest safety standards.

Characteristics

• High-level intrumentation inside the mixing tank

• Easy maintenance

• Numerous security detections

• Last generation electric motorization

Turnkey equipment with delivery, installation and training of on-site teams.

This tool is perfectly complementary to our modular internal mixer and allows to obtain a mixing line to optimize any scale-up process.

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Solid blender

- Agitator for the chemical industry

- In-line mixer

- Mixer-dispenser

- Compact agitator

- Laboratory homogenizer

- Volumetric mixer-dispenser

- Rotor agitator

- Automatic mixing and metering unit

- Blending system

- Conical blender

- High-capacity blender

- Modular agitator

- Polymer agitator

- Automatic mixing system

- Mixer for the rubber industry

- Thermo-regulated mixer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.