- Industrial machines and equipment

- Mixing and Dosing

- Granules loss-in-weight feeder

- Liad Weighing and Control Systems Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

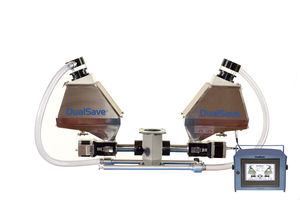

Granules loss-in-weight feeder ColorSave 1000gravimetricloss-in-weightsingle-screw

Add to favorites

Compare this product

Characteristics

- Product

- granules

- Type

- gravimetric, loss-in-weight, single-screw

- Applications

- for the plastics industry, for extruders, for injection molding machines, for blow molding machine, for masterbatch

- Other characteristics

- hopper, high-precision, automatic, high-capacity

Description

Advanced Single Component Gravimetric Feeder

ColorSave 1000 is a highly accurate and cost-effective single component masterbatch & additive gravimetric feeder for injection molding, extrusion, and blow molding machines, that offers significant cost-savings and production efficiency advantages for plastics manufacturers.

ColorSave 1000 is the original single component gravimetric feeder for injection molding machines and is still the only gravimetric feeder available with an internal weighing hopper – ensuring unmatched resistance to mechanical shocks and vibrations while providing the most accurate weighing and dosing.

The innovative design and proprietary algorithms found in the ColorSave 1000 ensure homogenous feeding, regardless of material density changes or other dynamic parameters.

Benefits of a Double Hopper

ColorSave 1000’s external hopper acts as a protective shell for the internal hopper; preventing operator contact, air drafts, and other factors from interfering with the weighing accuracy of the load cell. The mechanical separation of the weighing chamber from the screw feeder, motor, and additive loader provides precision and accuracy of additive feeding that is unmatched in the industry.

• Highly sensitive load cells

• Accurate and precise feeding

• Significant cost savings

Product Features

• ColorSave 1000 provides the industry’s highest precision of additive feeding.

• ColorSave 1000’s automatic calibration enables you to consistently feed at the desired set point.

• ColorSave 1000’s user-friendly design allows you to quickly clean and sterilize components between jobs.

VIDEO

Catalogs

ColorSave 1000

4 Pages

ColorSave 1000V

2 Pages

Other Liad Weighing and Control Systems Ltd. products

Feeders

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Volumetric dosing unit

- Liquids dosing unit

- Stainless steel agitator

- Horizontal blender

- Mixer-dispenser

- Solid dispensing system

- High-precision dispensing system

- Continuous dispensing system

- Powder dosing unit

- Gravimetric dosing unit

- Weight dosing unit

- Hopper dosing unit

- High-precision mixing and metering unit

- Dosing unit for the plastics industry

- Screw dosing unit

- Batch blender for the plastics industry

- Gravimetric mixer-dispenser

- Automatic mixing and metering unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.