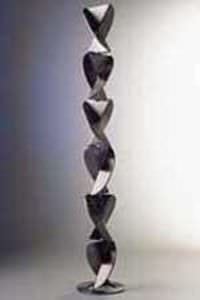

Dynamic mixer 98 seriesbatchfor liquidssingle-shaft

Add to favorites

Compare this product

Characteristics

- Technology

- dynamic

- Batch/continuous

- batch

- Product type

- for liquids

- Other characteristics

- single-shaft, helical

- Engine power

Max.: 200 kW

(271.92 hp)Min.: 15 kW

(20.39 hp)

Description

Parallel drives for heavy duties, optimize productivity and reduce downtime

FEATURES

Traditionally, internal gear drive components are subject to large axial and bending loads which are the primary source of unwanted gear deflection and misalignment. Left unchecked, these dynamic loads can significantly reduce gear life or cause sudden gear-drive failure. These loads are attributed to the fluid forces which act on the mixer shaft at the impellers.

SPX FLow Lightnin’s design isolates the gearing from the effects of these fluid forces through the following combination of design advantages:

• The lower quill shaft bearing experiences no external loading and does not support the mixer shaft in any way.

• Clearance between the mixer shaft and quill shaft ensures that no bending loads are imposed on the quill shaft, effectively isolating the gearing from the mechanical effects created by the fluid forces.

• The fixed bearing located below the gear drive in the seal cartridge absorbs radial reaction forces in addition to the axial loads. As a result, they are prevented from being transferred to the gear drive.

• The precise positioning of the fixed bearing within millimeters of the mixer seal faces minimizes shaft run-out and dynamic deflection to maximize seal life.

• Parallel shaft, double reduction design provides enhanced installation flexibility where there are space limitations on top of the vessel.

• Carburized and ground helical gearing helps ensure quiet operation and extended gear life.

• Dry well oil dam is integrated into the gear housing to prevent lubrication from leaking down the mixer shaft.

Catalogs

98 Series Mixers

4 Pages

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Homogenizer for the food industry

- Solid blender

- Vertical agitator

- Stainless steel agitator

- Agitator for the chemical industry

- In-line mixer

- Powder blender

- Solid/liquid homogenizer

- Horizontal blender

- Agitator for the pharmaceutical industry

- Construction agitator

- Turbine agitator

- Paddle blender

- Homogenizer for the cosmetics industry

- Compact agitator

- Automatic homogenizer

- Explosion-proof agitator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.