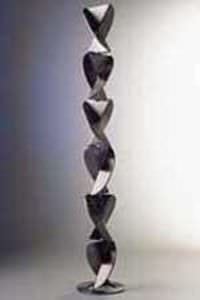

Turbine mixer Line Blender™continuousfor liquidshigh-shear

Add to favorites

Compare this product

Characteristics

- Technology

- turbine

- Batch/continuous

- continuous

- Product type

- for liquids

- Other characteristics

- high-shear

- Applications

- for the food industry, for the chemical industry, water treatment, for the petroleum industry, for the paper industry

Description

Line Blenders are typically used for premix or fast reaction applications and a variety of blending applications in chemical processing, food processing, petroleum refining, pulp & paper processing and waste water treatment

• Mix continuously with a tank

• Supplied complete with motor and impeller(s)

• Excellent for continuous process applications

• Provide almost instantaneous mixing

• More space-efficient than conventional tank/mixer systems

• Economical to operate and maintain

Typical Applications

Chemical Processing - Used for all blending requirements, disperse cakes from filter and centrifuges. Mix components quickly for reactions and mass transfer. Provide additional shear in re-circulation lines. Premix for in-tank installations.

Food Processing - Blend syrups and sugar solutions with water. Mix caustic solution with vegetable oils for refinement.

Petroleum Refining - Used to treat petroleum products and organic chemicals. Blending lube and fuel oil components with additives. Contacting crude oil with fresh water for desalting.

High Viscosity Blending - Blend additives with a high viscosity material ie: adding a catalyst to rubber polymerization streams.

Pulp and Paper Service - Control consistency by blending stocks from different sources. Mixing additives, color, chemicals and dilution water into paper stock.

Water and Waste Treatment - Flash-mix water treating chemicals into wastewater stream.

Catalogs

Line Blender In-Line Mixers

6 Pages

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Homogenizer for the food industry

- Solid blender

- Vertical agitator

- Stainless steel agitator

- Agitator for the chemical industry

- In-line mixer

- Powder blender

- Solid/liquid homogenizer

- Horizontal blender

- Agitator for the pharmaceutical industry

- Turbine agitator

- Construction agitator

- Paddle blender

- Homogenizer for the cosmetics industry

- Compact agitator

- Automatic homogenizer

- Explosion-proof agitator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.