- Metrology - Laboratory

- Metrology and Test Equipment

- Video extensometer

- LIMESS Messtechnik und Software GmbH

Video extensometer RTSStensiletransversal

Add to favorites

Compare this product

Characteristics

- Options

- tensile, video, transversal

Description

Contactless Strain Sensor for Material testing

- For standardised tensile tests

- Easy specimen marking

- Optional measurement of transversal strain

- Strain from 0,0005% to 1000%

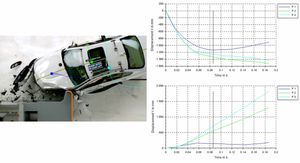

The RTSS Videoextensometer measures the longitudinal and transversal strain during material tests (e.g. tension, compression tests). The system can be used for flat and round specimen at field of view (FOV) of 10mm to 1000mm. For rope testing a FOV up to 5m can be realized. Strains from 0.0005% to 1000% can be measured.

The RTSS (Real Time Strain Sensor) can be intregated via different interfaces as a strains sensor and can be fully integrated in a tensile test machine. Further offline analysis modules for the determination of strain distributions and crack length (e.g. long term tests) are available.

Contact less

No clamping =no mechanical influence of a mechanical sensor to the specimen:

• High precision

• No specimen influence/damage

Measurement of the strain at failure (no mechanical limitation of the sensor)

Material independent

Wide application field on all materials

Soft and rigid materials can be tested

Strains from 5µm/m to 1000%

Flexible field of view

Specimen size of a few mm to some m

For strains from 20µm/m until 1000%

Used at small and large tensile test machines

One system for

• Different testing machines in one laboratory

• Different tasks

Camera-based

Easy specimen marking

Can be used for tiny specimen due to enlarged image visualisation

Recording of movies for documentation and quality control

High precision, high speed

Simultaneous measurement of longitudinal and transversal strain

Live-camera-view

Fast system setup

Precise specimen alignment

Catalogs

RTSS | Videoextensometer

2 Pages

Other LIMESS Messtechnik und Software GmbH products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.