- Metrology - Laboratory

- Inspection and Monitoring

- Camera for the automotive industry

- LIMESS Messtechnik und Software GmbH

Camera system for the automotive industry Q400for aerospace applicationsfor materials testingCCD

Add to favorites

Compare this product

Characteristics

- Applications

- for the automotive industry, for aerospace applications, for materials testing

- Sensor

- CCD

- Other characteristics

- high-speed

Description

Full field Deformation Measurement

-Flexible strain sensor for a wide application range

-Field of View of 1x1mm² to 10x10m²

-Easy usage and fully automatic calibration within 20 seconds

-Integrated Analysis modules for automatic post processing

-Certifiable after ISO9513 and VDI/VDE2626

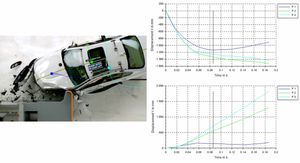

With the Q400 system, the 2D or 3D deformation analysis is performed in a precise, fast and user-friendly manner. The modular system is also characterized by the high flexibility of the optical setup and thus can be optimally adapted to the application. The intuitive measurement software Istra4D also provides the associated measurement accuracy for each measured value (displacement, deformation, strain, 3D coordinates, etc.). Thanks to optimized algorithms, Istra4D can resolve local effects, e.g. in crack growth, better than other DIC systems. Using a special cluster approach, up to 16 cameras can be used in a Q400 system, which achieves better surface coverage for complex component geometries and higher measurement accuracy.

• Spatial measurement of 3D coordinates, displacements and strain tensors shown as 2D overlay or 3D model

• Fully automatic calibration with real-time tracking and quality feedback

• 'Genuine' multi-camera system - Fully integrated system with up to 8 cameras for improved accuracy and surface coverage on complex surfaces and complete detection of a cylinder.

• 4-camera system for simultaneous measurement of the front and rear sides as well as thickness and thickness change.

• Modular software package for image acquisition, evaluation and visualization.

• Powerful integration of CCD and high-speed cameras

Catalogs

Other LIMESS Messtechnik und Software GmbH products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.