- Products

- Cladding machine

- Lincoln Electric Deutschland

Cladding machine

Add to favorites

Compare this product

Description

STRIP CLADDING PROCESSES

Cladding is a fundamental process in the pressure vessel industry and is applied across whole spectrum of applications, from Nuclear, Oil and Gas industries to Chemical Processing equipment and steelmaking. Cladding is required on the process side of high pressure critical process plant equipment to provide corrosion resistance against highly severe corrosive service fluid or to increase wear resistance of a component being subjected to heavy wear and tear applications e.g. continuous casting rollers in steel mills.

Submerged arc strip cladding

• The arc causes more penetration into the base material, resulting in dilution levels of ~20%.

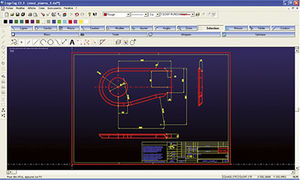

• 3D part visualization and rotation,

• Deposition rate: 12-14 kg/h for 60 x 0,5 mm strip.

• Current range restricted to limit dilution.

Catalogs

No catalogs are available for this product.

See all of Lincoln Electric Deutschland‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.