- Products

- Catalogs

- News & Trends

- Exhibitions

Programmable electronic control unit iCon®CAN Busfor vehiclessafety

Add to favorites

Compare this product

Characteristics

- Options

- for vehicles, CAN Bus, programmable, safety

Description

Linde electronic control units of the iCon series feature high mechanic and electric robustness.

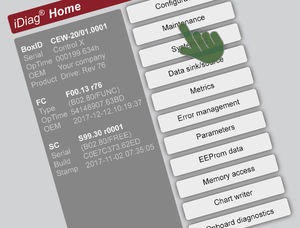

Core components are a function controller and a safety control. Due to the redundant design, the unit can provide safety functions up to performance level d (DIN EN ISO 13849-1) and thus is able to meet global legal standards for on-road machinery. iCon controls are used individually or combined, for hydraulic and electric drives, as well as combinations of both. Additionally to the drive components, the combustion engine, as well as components such as sensors, joysticks and pedals can be integrated in the control system. Upon delivery, the control is preconfigured with the desired functions, machine characteristics and vehicle data. Single parameters can be configured easily and without programming know-how via the diagnosis software LinDiag and iDIAG. The control can thus be adapted to different power-classes and equipment of a machine or to comply with the specific legal requirements of different countries.

Advantages

optimum cooperation with hydraulic Series 02 components and electric drive components from Linde

high availability and reliability

advanced safety level due to parallel safety controller and redundant architecture

complete drive train management by just one electronic control unit with additional definable digital and proportional inputs and outputs

individually adaptable machine behaviour

CAN bus

easy parameterization and diagnosis own diagnostic tool (LinDiag, iDIAG)

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.