- Products

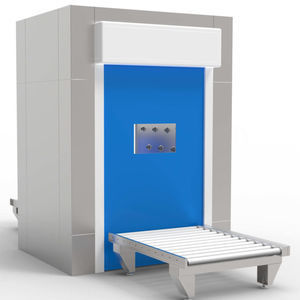

- Sterility testing containment isolator

- Litek Industrial S.L.

- Products

- Catalogs

- News & Trends

- Exhibitions

Sterility testing containment isolator modularcompactstainless steel

Add to favorites

Compare this product

Characteristics

- Applications

- for sterility testing

- Configuration

- modular, compact

- Other characteristics

- stainless steel, laminar flow, with HEPA filter

Description

Sterility testing is a necessary process to be able to release sterile drug production batches. A representative sample should be taken from the batch produced and tested for sterility. It is critical that this quality control is carried out without errors, so that the test shows the true test result and not false results. Therefore, LITEK Sterility Test Isolators offer the possibility to perform these tests safely and minimise the chances of false positives.

With a modular isolator solution, we can adapt to the customer’s needs, depending on the number of tests to be performed daily, with different isolator configurations, sizes, Pass Through SAS, and material and waste outlets.

Basic equipment

• Chamber made of stainless steel AISI 316L, 3mm thick, internal polishing Ra<0.6

• Compact ventilation module, for recirculation and aeration.

• Tempered glass doors with inflatable gasket seal.

• Electrical panel incorporated in annex module.

• LED lighting.

Automation

• Siemens PLC

• Beckhoff HMI industrial PC

• Beckhoff 15.6″ touch screen monito

Optional

• Material airlock.

• Waste port.

• RTP (Rapid Transfer Ports).

• Double HEPA H14 impulsion line filtration.

• HEPA H14 extraction line filtration, close to chamber.

• 21 CFR Part 11.

• Oval gloves.

• Glove holders for H2O2 disinfection.

• Viable / and non-viable particle monitoring.

• Catalytic Filter.

• H2O2 monitoring, high and low concentrations.

• Temperature and humidity monitoring.

• Temperature and Humidity Control.

• SCADA system.

• Laminar flow.

• Turbulent flow.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.