- Environment - Health - Safety

- Personal Protective Equipment

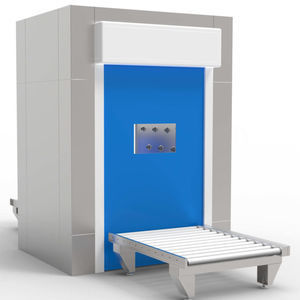

- Floor-standing shower cubicle

- Litek Industrial S.L.

- Products

- Catalogs

- News & Trends

- Exhibitions

Floor-standing shower cubicle airstainless steel

Add to favorites

Compare this product

Characteristics

- Mounting

- floor-standing

- Other characteristics

- air, stainless steel

Description

Solution for microelectronic, automotive or related industries in transit to classified or high particle classification areas.

The person dedusting process is carried out by blowing air at high speed, using nozzles and filtration G4 and H14.

Validated solution, developing the dedusting cycle and calculating the class recovery time inside.

The equipment includes:

• Structure in lacquered steel. Option AISI 304 stainless steel.

• Interlocked hygienic glass doors.

• High-speed blowing nozzles to ease the removal of the deposited dust.

• Air ionisation option.

• Siemens control system and cycle status beacon.

• Internal Illumination with colour code, according to cycle phase.

• Blowing of the person in all directions for the optimization of the process.

Other data:

• Drive speed: 30 m/s

• Bottom filtration to allow dust collection.

• Recirculation hour 1200 r/h.

• Configurable cycle time, depending on the desired class recovery factor.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.