- Packing - Handling - Logistics

- Conveying

- All material transfer system

- Litek Industrial S.L.

- Products

- Catalogs

- News & Trends

- Exhibitions

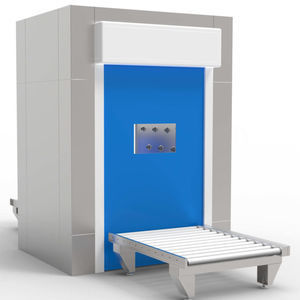

All material transfer system

Add to favorites

Compare this product

Characteristics

- Product applications

- for all materials

Description

Material transfer systems (MTS) are designed to allow a safe material transit between different classification zones.

Litek Pharma has different types of material transfer systems that allow the entry and exit of materials to and through different classification zones. There are different models, sizes and configurations depending on the necessities of the room and the project. Material transfer systems are totally configurable and adaptable to every zone and are integrates in the clean room.

Litek Pharma’s material transfer systems feature coloured illumination for quick and easy identification of the cycle status of the device.

Litek Pharma offers different applications in the transfer process, such as the option of self-ventilation, dedusting application or low temperature disinfection by UV, or H2O2.

• Static MTS.

• Ventilated MTS.

• Ventilated MTS with UV decontamination.

• Ventilated MTS with H2O2 decontamination.

Basic equipment

• Chamber made of AISI 304 stainless steel sheet/ optional 316.

• The surface finish of the stainless steel is less than 0.6 µm Ra on the inside and 1.2 µm Ra on the outside.

• The MTS chamber is designed to be airtight with inflatable gasket seal.

• Design according to the cGMP/FDA standards.

• Interior construction with rounded corners provides smooth interior surfaces that prevent cracks.

• Tempered glass doors.

• Maximisation of the hygienic finish thanks to the glass door that will cover the front of the equipment.

• Electromechanically interlocked doors that prevent the simultaneous opening of both doors.

• Colour coding for the easy identification of the cycle status.

• Anodised aluminium door hinges.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.