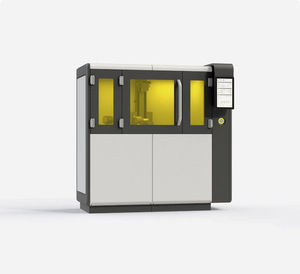

Ceramic 3D printer CeraFab S seriesLCMindustrialhigh-performance

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- ceramic

- Technology

- LCM

- Applications

- industrial

- Other characteristics

- high-performance, high-speed

- X travel

64 mm, 102 mm, 192 mm

(2.52 in, 4.02 in, 7.56 in)- Y travel

40 mm, 64 mm, 120 mm

(1.57 in, 2.52 in, 4.72 in)- Z travel

320 mm

(12.6 in)

Description

• Boosted productivity

• Unmatched precision

• Consolidated reliability

Industry-leading and trusted 3D printers, designed for scalability and ready for advanced developments and serial production.

The CeraFab System family is the ultimate choice for enabling the industrial serial production of high-performance ceramics using additive manufacturing. Each machine in the CeraFab System family, consisting of the S25, S65 and S230, offers a full 3D printing system for advanced developments. A total of four production units can be combined, making it easy to scale-up and enabling the rapid manufacture of exceptional ceramic components. From small-scale to large part production, these machines can accommodate all types of high-quality 3D printing projects thanks to their different build volumes and have the fastest building speed on the market. The current generation of projectors with WQXGA resolution, in combination with an objective lens specially developed for the process, ensures the absolute precision of printed components – even in the micrometer range.

Industrial Internet of Things and Industry 4.0 ready

A central element of the CeraFab System is the automatic creation of a database for storing and handling process data, which facilitates the seamless documentation of print jobs. An optional add-on allows for real-time monitoring and control of the process via live-video remote transmission.

The CeraFab System is our answer to all questions about the industrial series production of additively manufactured high-performance ceramics.

VIDEO

Catalogs

Related Searches

- Additive manufacturing machine

- Industrial 3D printing machine

- Plastic 3D printing machine

- High-speed 3D printer

- High-performance 3D printing machine

- Metal additive manufacturing machine

- Medical additive manufacturing machine

- Dental additive manufacturing machine

- 3D printing software

- Multi-material 3D printer

- Ceramic 3D printer

- Design 3D printing software

- Process control 3D printing software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.