- Products

- Catalogs

- News & Trends

- Exhibitions

Steam boiler hot watergasheat-recovery

Add to favorites

Compare this product

Characteristics

- Product

- steam, hot water

- Power source

- gas

- Other characteristics

- heat-recovery

- Pressure

Min.: 0 MPa

Max.: 1.6 MPa

Description

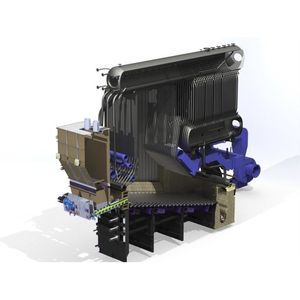

At the request of customers, the heat recovery boiler can be made with two parallel passages of flue gases, each of which is equipped with a separate system of dampers and bypass flue gases ducts, while it has a common water circuit. This arrangement allows to reduce metal consumption, the number of auxiliary components and minimize overall dimensions.

The heat recovery boiler can be equipped with additional package of a finned tube water economizer, which is installed on the outlet gas duct. This allows to cool the flue gases to the optimum temperature.

The heat recovery boiler is designed for utilize flue gases with temperature up to 500 and produce steam or hot water with an operating pressure up to 1,6 MPa.

Waste Heat Boiler for CHP

Heat recovery steam boiler is used to produce steam by cooling flue gases after cogeneration plants based on internal combustion engines or other technological equipment

The heat exchanger is a single-pass tubular smoke-fired boiler with a system of dampers and bypass gas ducts for the possibility of shutting down the boiler without stopping the main equipment.

Related Searches

- Heat exchanger unit

- Heater

- Tubular heat exchanger

- Stainless steel heat exchanger unit

- Gas/liquid heat exchanger unit

- Steam boiler

- Hot water boiler

- Gas heater

- Gas boiler

- Industrial heat exchanger unit

- Air heater

- Solid fuel boiler

- Copper heat exchanger

- Shell and tube heat exchanger

- Smoke tube boiler

- Industrial boiler

- Titanium heat exchanger

- Biomass boiler

- Pressure heat exchanger

- Duct heater

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.