- Machine-tools

- Finishing Machine

- Plastic polishing machine

- Logitech Limited

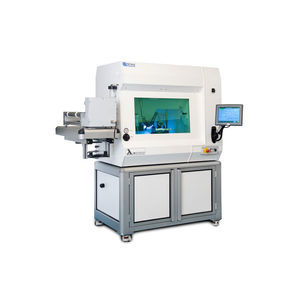

Hard plastic polishing machine CMP-Orbis precision

Add to favorites

Compare this product

Characteristics

- Machined material

- hard plastic

- Other characteristics

- precision

Description

The Logitech Orbis CMP system is a precision engineered, floor standing CMP tool ideally suited for R&D environments. Typically the Orbis CMP System is used in applications which conduct pilot production tests with optimum analytical capabilities and enhanced processing performance.

The system capabilities can be adapted to include:

Back-end IC manufacturing,

Micro-Electromechanical Systems (MEMS) fabrication,

Opto-MEMS

Bio-MEMS fabrication.

Low cost solution – high value results

The ability to conduct pilot process tests normally requires expensive production level systems, yet the Orbis achieves this capability in a cost effective system. Incorporating enhanced features and high-tech functionality, the Orbis CMP System achieves superior processing capabilities to those usually offered in a system of this size.

Flexible use of operation

In addition to its ability to replicate production level environments, the Orbis is also suitable for more traditional R&D usage. This includes small batch production and pilot production testing. The system is capable of processing all die, wafer and part wafers up to 200mm (8″) diameter using a dedicated carrier. As with previous Logitech CMP equipment, templates and shims can be utilised or the samples can be mounted directly to the sample carriers.

Key Features

Ideal for R&D environments and pilot process testing

High capacity workspace for samples up to 2 of 200mm (8″)

Downloadable data for analysis of process parameters

Laboratory scale footprint

Industry standard pad conditioning to maintain optimum pad life

VIDEO

Catalogs

Other Logitech Limited products

Chemical Polishing & Chemical Mechanical Polishing

Related Searches

- Polishing unit

- Metal polishing unit

- Automatic polishing unit

- Surface polishing machine

- Finishing polishing machine

- CNC polishing machine

- Lapping machine

- Plastic polishing unit

- Precision polishing machine

- Sheet polishing machine

- Optical polishing machine

- Bench-top polishing unit

- Polishing lapping machine

- Lapping polishing machine

- Ceramic polishing machine

- Variable speed polishing machine

- Precision lapping machine

- Chemical-mechanical polishing machine

- Planetary polishing machine

- Hard material lapping machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.