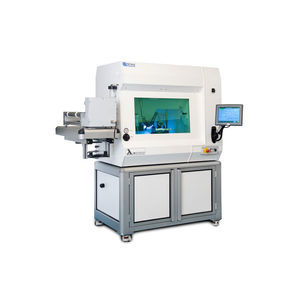

Plasma cleaning system SWC4000 automaticfor the semiconductor industry

Add to favorites

Compare this product

Characteristics

- Technology

- plasma

- Operational mode

- automatic

- Applications

- for the semiconductor industry

Description

Logitech’s SWC4000 offers Single Wafer Cleaning Stand-alone System for damage-free, optimised cleaning for wafers and masks used in the MEMS and Semiconductor Industry.

The SWC4000 system provide controlled chemical dispensing capabilities, allowing for enhanced particle removal from the specimen surface. Utilising the chemical dispensing functionality alongside the megasonic cleaning technology allows for highly optomised cleaning.

The released particles are removed from the substrate surface by sweeping off the particles with the radial flow of the de-ionised water. Without this feature, stationary cleaning tanks allow for a greater number of particle reattachments therefore requiring further cleaning time to remove.

The SWC4000 system is capable of in-situ spin drying with heated N2 or IPA. “Dry-In-Dry-Out” one step processing is possible with the lowest capital investment and cost of ownership. The process time for SWC systems can vary between 3-5 minutes per substrate, depending on the size and cleaning options used.

The SWC4000 system has a small footprint, making them the ideal solution for any clean room with limited space looking for superior cleaning abilities across a variety of substrates.

Key Features

Designed for the cleaning of single wafers up to 300mm/12″

Ideal for the cleaning of patterned and un-patterned, Germanium (Ge), Galluim Arsendie (GaAs) and Indium Phosphide (InP) wafers

Perfect solution for post CMP cleaning, cleaning of diced chips on a wafer frame, cleaning after plasma etch or photoresist stripping, mask blanks or contact mask cleaning and optic lense cleaning

Catalogs

No catalogs are available for this product.

See all of Logitech Limited‘s catalogsOther Logitech Limited products

Chemical Polishing & Chemical Mechanical Polishing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.