- Environment - Health - Safety

- Waste Treatment

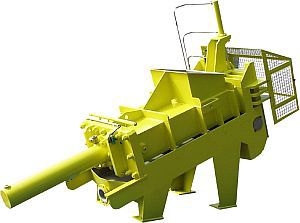

- Food waste treatment plant

- Lohse GmbH, Maschinenbau

Organic waste treatment plant for food

Add to favorites

Compare this product

Characteristics

- Type of waste

- organic, for food

Description

for biowaste, foodwaste and household waste

Process technology for various organic waste

for the wet fermentation

By the Lohse wet treatment technology with the help of „pulper-systems“ and sieving, a pumpable and well fermentable suspension is obtained with very low content of impurities.

First, in the waste pulper, the organic waste is dissolved by strong agitation while the heavy materials are separated.

In the downstream sieving device is the careful separation of another impurities from suspension. The suspension thus obtained can be pressed in a following digesting system.

The Lohse waste pulper and the following sieving device are manufactured in different sizes, according to the quantity of waste up to approx. 12 tons per hour.

Optimal separation of impurities by a wet liquid treatment

-> low load in the suspension with impurities

-> low formation of floating roofs

Separation of impurities at the beginning of the process

-> protection the following pumps and aggregates

-> low pollution of digestable suspension

It can be processed organic waste with drymatter content (DM) of about approx. 15% DM (e.g. food waste) to about approx. 50% DM (e.g. gassilage, manure, pre-sorted houshold waste)

Catalogs

No catalogs are available for this product.

See all of Lohse GmbH, Maschinenbau ‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.