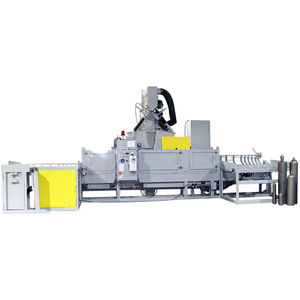

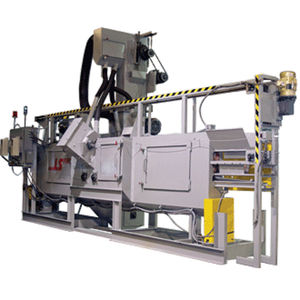

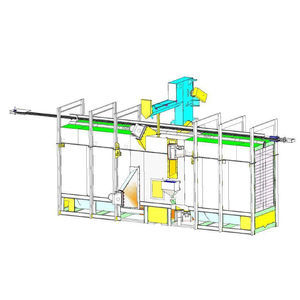

Manual shot blasting machine Monorail 48×120for metalautomatic

Add to favorites

Compare this product

Characteristics

- Type

- manual

- Applications

- for metal

- Other characteristics

- automatic

Description

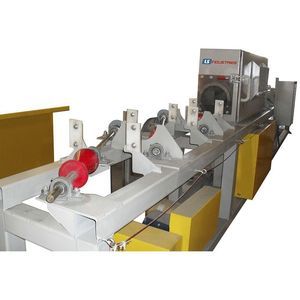

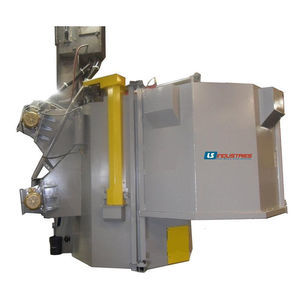

Whether you are adding a new product handling monorail to your facility or you already home something in place we can design the 48×120 Monorail blaster to work for your needs. Items hanging in the blast zone are blasted by the SureShot™ blast wheel in an ‘X’ pattern, ensuring that all sides are blasted. The monorail variable speed drive allows you to adjust the travel speed of your parts through the blast zone to get the proper blasted finish based on the condition of the parts. The blast cabinet is constructed of heavy-duty manganese with replaceable manganese wear plates. Additional elements that make LS Industries machines easier to maintain are the multiple access doors located at the elevator, the augers and the blast zone. Also note, it is not necessary to put the blaster into a pit but it can be done to accommodate the monorail line.

Features

Full Upper Air Wash

Optional

Medium Size Air Wash

Yes

Automatic Shot Adder

Yes

Elevator Jam Shutdown

Yes

Parts Sensor

Yes

Shot Hopper with High/Low Shot Sensor

Optional

Heavy Duty Urethane Flaps in Blast Zone

Yes

Parts Blow Off**

Optional

Monorail Conveyor

Optional

Maintenance/Service Platform

Optional

Dual Elevator System

Optional

Technical Specifications

Work Envelope

48″W x 120″H

Overall Dimensions

30′ x 19′ x 19′

No. of Blast Wheels (STD)*

8ea x 30HP

Dust Collector***

DCC-40-A

VIDEO

Catalogs

No catalogs are available for this product.

See all of LS Industries‘s catalogsRelated Searches

- Automatic washing machine

- Water washing machine

- Industrial washing machine

- Stainless steel washing machine

- Process washing machine

- Blast machine

- Spray washing machine

- Metal shot blasting machine

- Parts washing machine

- Solvent washing machine

- Manual washing machine

- Blast room

- Automotive washing machine

- Automatic blast machine

- Mobile cleaning equipment

- Ultrasonic tank

- Hand blast cabinet

- Industrial ultrasonic tank

- Degreasing washing machine

- High-pressure washing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.