- Materials - Tools - Components

- Lubrication

- Oil lubrication unit

- Die Lubrication Solutions Srl

Oil lubrication system LUBSYSTEM 600 seriesmulti-pointfor presseshydraulic

Add to favorites

Compare this product

Characteristics

- Lubricant

- oil

- Type

- multi-point

- Applications

- for presses

- Power source

- hydraulic

- Other characteristics

- automatic, programmable

Description

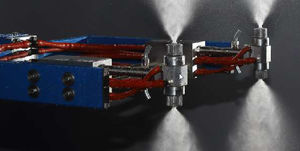

This top of the line system is characterized by an arm movement with a four thread-start worm screw, 40 Ø, 40 pitch with recirculating ball screw controlled by a brushless motor. The spraying group, which can contain one or more heads, is supported by a linear bearing with slides. The work cycle is managed by a PLC with a touch screen panel that allows you to perform both spot and pass spraying, select the lubricating heads, and set spraying time. The management program includes the ability to save different lubrication-cycle settings to be reused for

repetitive details.

In order to find the optimal distance between the mold and the lubricating head, it is possible to adjust the height of the arm through the machine’s set-up program.

The Lubsystem 600 series also comes with a programmable automatic washing system for the release agent circuit and an independent die cleaning air system.

FEATURES:

Electronic movement with brushless motor and spherical screw with up to 4 lubricating heads

Limitless lubrication functions and times

Simple and intuitive programming

Easy removal to facilitate maintenance on the press

Height adjustment of the spraying group with encoder

Automatic washing system

ADVANTAGES:

A single machine to cover all types of lubrication:

Single-point, multiple-points on the same mold, or even spread on a long and complex mold

Electronic movement

Highly performant for presses from 1000 to 8000 tons

Possibility of air cleaning system only if necessary, heads with transversal translation

Height adjustment

Heads with transversal translation

Catalogs

No catalogs are available for this product.

See all of Die Lubrication Solutions Srl‘s catalogsOther Die Lubrication Solutions Srl products

HOT FORGING LUBRICATION

Related Searches

- Lubrication system

- Oil lubrication system

- Automatic lubricator

- Electric lubrication system

- Automatic lubrication system

- Single-point lubricator

- Compact lubrication system

- Multi-point lubricator

- Spray lubrication system

- Multi-point lubrication system

- Tape lubrication unit

- Programmable lubrication system

- Press lubrication system

- Mechanical lubricator

- Sheet metal lubrication unit

- Hydraulic lubricator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.