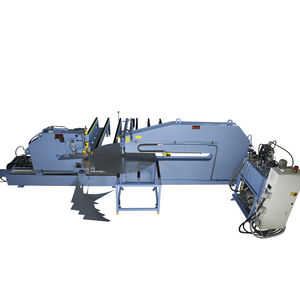

Circular shear 10 serieshydraulicsheet metalmotorized

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Application

- sheet metal

- Type

- circular

- Other characteristics

- motorized, automatic

- Plate thickness

Min.: 0 mm

(0 in)Max.: 10 mm

(0.39 in)- Pressing force

400 N

Description

This type of machines has always represented one of the strong points of the company production. Our machines perform cutting and beading (on demand) with a high quality of finish and absolute repeatability of the pieces. This series stands out for reliability and accuracy.

Turret tailstock with clamping piston, with central hole

Adjustment of cutting diameter through gear motor and visualization with digital display.

Guiding of cutting / beading head through ball rail system.

Guiding of tailstock through ball rail system.

automatic insertion of the wrinkle-breaker device

high productivity thanks to the high cutting speed

blade descent with hydraulic control with slowdown device for gentle cutting in more revolutions

Machine available in three models 10/3500 M, 10/5000 M or 10/6500 M, depending on the maximum diameter to work. It can be supplied also with recirculating ball screws and d/c motor for the quote positioning with storage of programs and quick repositioning (6 m / min).

Optionally these machines can be provided with extension of the hub for working cones.

Catalogs

No catalogs are available for this product.

See all of Lucas‘s catalogsRelated Searches

- Punching center

- Lucas sheet metal shear

- Automatic punching press

- Manual lever shear

- Lucas strap shear

- Metal snips

- Punching machine punching machine

- Lucas automatic shear

- Cutting punching press

- Motorized shear

- Pneumatic shear

- Forming punching press

- Semi-automatic punching press

- Lucas circular shear

- Semi-automatic shear

- Flanging machine shear

- Welding punching machine

- Fire extinguisher punching machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.