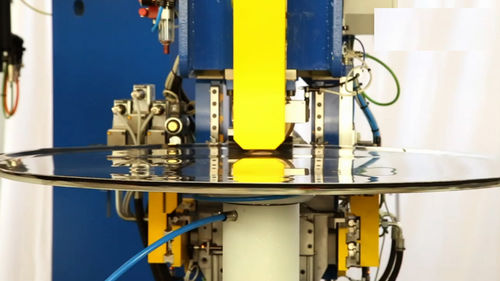

Motorized flanging machine Tanko 3.8hydraulicfor round parts

Add to favorites

Compare this product

Characteristics

- Type

- motorized, hydraulic

- Treated product

- for round parts

Description

Machine for flanging polycentric or round heads dished, flat or conical (typically pre-cut by laser or plasma cutter) without use of copying templates.

Designed to be the perfect solution in fields of application such as manufacturing of truck and trailer tank head or food and wine storage, fermentation tanks and chemical and pharmaceutical industry.

Clamping: the tank head is positioned on a vacuum seal support (without any hole or marking).

Centering: the workpiece is roughly centered by the operator with the aid of mechanical stoppers and of a laser beam, then the machine performs by itself automatically the accurate software centering.

Flanging: the movement of the motorized rotating head is controlled by servo motors and sliding on recirculating ball bearings on the portal. The flanging group is composed by no. 3 hydraulic controlled rollers (form, shape and blank-support) for excellent superficial finishing and absolute repeatability of the pieces.

Programming: the profile of the workpiece is imported in AutoCAD format via a USB port.

Catalogs

No catalogs are available for this product.

See all of Lucas‘s catalogsRelated Searches

- Punching center

- Forming machine

- Automatic punching press

- Metal forming machine

- Lucas flanging machine

- Punching machine punching machine

- Cutting punching press

- Forming punching press

- Hydraulic forming machine

- Semi-automatic punching press

- Lucas automatic flanging machine

- Precision forming machine

- Swaging machine

- Lucas sheet metal flanging machine

- Pipe forming machine

- Lucas motorized flanging machine

- Lucas hydraulic flanging machine

- Multi-station forming machine

- Cutting forming machine

- Vertical forming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.