- Production Machines

- Other Manufacturing Equipment

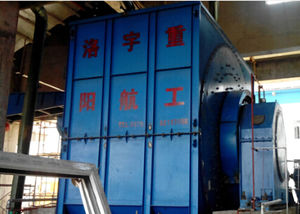

- Mill with rods

- Luoyang Luoyang Yu, Science & Technology Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Mill with rods MBS (G) serieshorizontalgrainbuilding materials

Add to favorites

Compare this product

Characteristics

- Technology

- with rods

- Orientation

- horizontal

- Product applications

- grain, building materials

- Output

Min.: 1 t/h

(1 lb/s)Max.: 8 t/h

(5 lb/s)- Motor power

22 kW, 630 kW

(29.91 hp, 856.56 hp)- Machine length

Min.: 4,980 mm

(196 in)Max.: 14,600 mm

(575 in)- Machine width

Min.: 800 mm

(31 in)Max.: 8,800 mm

(346 in)- Machine height

Min.: 2,020 mm

(80 in)Max.: 6,800 mm

(268 in)- Machine weight

Min.: 6 kg

(13 lb)Max.: 160 kg

(353 lb)

Description

The rod mill has both dry and wet process available for customer choice. The mill will be equipped with magnetic iron remover when it’s used in grinding of the quartz sand, dolomite and monazite etc. It’s widely applied in various ore and rock processing in metal mines, hydro-power and building materials and so on.

1.The power can be saved more than 40% compared with old type. The product size is uniform with a little coarse particles and mud. The over-rushing is light.

2.The discharge granularity is more uniform with higher production which is suitable for ores of different hardness (Moh’s hardness 5.5~12)

1. The rod mill is named as it has the steel rod as grinding medium. Normally it adopts the wet overflow process as an open circuit grinding at first stage. It’s widely used in the first grinding of artificial sand making, mineral processing plant and power sector of chemical plant, etc.

2. The product grain characteristics of the rod mill is relative with the grinding process. When the rod impact the materials, the coarse ones are impacted first, then the fines to reduce thus the over-crushed risk. When the rod move up along the lining, they have the coarse grains between them as rod screen, which allows the fine ones passing through the rod gap, facilitating thereby the crushing of coarse grains or concentrate the coarse grains in the area where the rods can break easily. Therefore the product of the rod mill is uniform with lighter over-crushing.

Other Luoyang Luoyang Yu, Science & Technology Co., Ltd products

Mill Series

Related Searches

- Grinding mill

- Production machine

- Screening unit

- Bulk material screening unit

- Automatic making machine

- Horizontal grinding mill

- Vertical grinding mill

- Food lump breaker

- Vibrating sieving machine

- Building materials grinding mill

- Sieving machine for the food industry

- Compact grinding mill

- Mineral mill

- Construction screening unit

- Powder grinding mill

- Rotary drum grinding mill

- Linear vibrating screening unit

- Process screening machine

- Ball grinding mill

- Metal mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.