- Production Machines

- Other Manufacturing Equipment

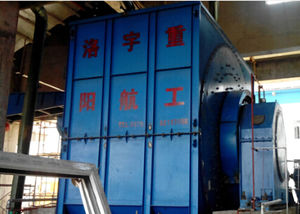

- Horizontal mill

- Luoyang Luoyang Yu, Science & Technology Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Horizontal mill for powdersfor coal grindingfor the chemical industry

Add to favorites

Compare this product

Characteristics

- Orientation

- horizontal

- Product applications

- for powders, for coal grinding

- Sector

- for the chemical industry, for the metallurgical industry

Description

cement, coal-fired power, metallurgy & chemistry etc

Suitable materials: Coal powder

the air swept mill is suitable for coal grinding. When the rotary kiln operates with coal powder as combustibles, it requires that the fineness of pulverized coal should be 200 sieve mesh accounted for more than 85%, and the moisture is less than 2%, for this purpose the air swept mill is ideal equipment by its fine grinding and drying features.

1. The mill is composed essentially by feeding, discharge, rotary and transmission parts (reducer, pinion, motor and electrical control unit). Other main components are: trunnion made by casting; inner lining being replaceaple, girth gear finished by casting and gear-hobbing machining and the wear-resistant liners applicable.

2. Steady running, convenient operation

The materials are sent in the mill through the feeding device, and the hot air is fed via air inlet pipe. With the rotation of the mill, the heat exchange between materials and hot air is performed in the mill, meanwhile the materials are dried, ground by the medium. The fine materials are finally discharged from the mill with the hot air

Other Luoyang Luoyang Yu, Science & Technology Co., Ltd products

Mill Series

Related Searches

- Grinding mill

- Production machine

- Screening unit

- Bulk material screening unit

- Automatic making machine

- Horizontal grinding mill

- Vertical grinding mill

- Food lump breaker

- Vibrating sieving machine

- Building materials grinding mill

- Sieving machine for the food industry

- Compact grinding mill

- Mineral mill

- Construction screening unit

- Powder grinding mill

- Rotary drum grinding mill

- Linear vibrating screening unit

- Process screening machine

- Ball grinding mill

- Metal mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.