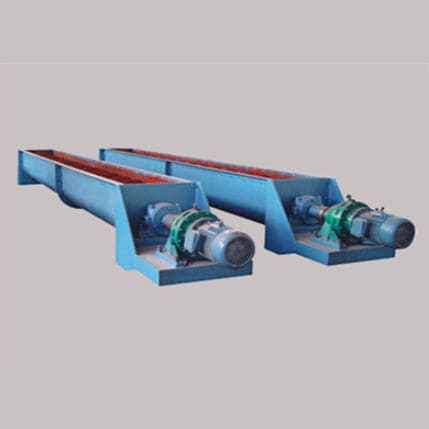

The layout of the LS worm feeder:

It normally consists of the machine body, feeding and discharging devices and driving device.

LS feeder is widely used in many fields, such as building material, metallurgy, chemistry, electricity, coal, mechnical, light industry, food etc. it can convey power, granual and small material, such as cement, coal powder, food, chemical fertilizer, lime-ash, sand, hard coke etc. it is can not applicable for the easy spoil, sticky and clotted material. Its working temperature is -20~40℃, while the material temperature should be -20~80℃. The feeder can be positioned horizontally or inclined. But the inclination angle should be less than 15°.

1.Big bearing capacity, safe and reliable.

2.Adaptable, easy maintenance, and long lifespan.

3.Small, high speed, convey the material fast and uniformly.

4.The cleaning device locates at the discharge end. The feeding position is flexible. The whole equipment is adaptable with low noise.

5.The sealing is good and the outside shell is made from seamless steel tube. The ends are connected by the flanges with good rigidity.