Product Introduction

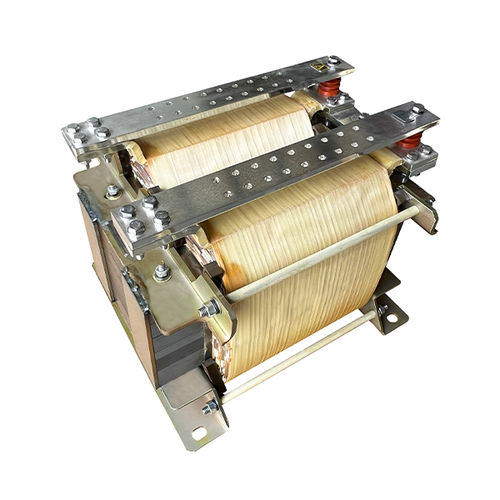

The DC filter reactor is a crucial component in the industrial field. It is installed in the DC circuit after the three-phase transformer rectification and forms an LC filter circuit with capacitors to filter out the ripple current for stable current and voltage.

Features

1.Advanced Process Ensures Performance:

With VPI treatment, insulation and heat conduction are enhanced. It improves the coil's corona resistance, reduces partial discharge, ensures stable and efficient operation, prolongs service life, and adapts to complex industrial working conditions.

2.Efficient Operation with Low Energy Consumption:

The ingenious design and optimized magnetic circuit reduce hysteresis and eddy current losses. It can still efficiently convert electrical energy during large current transmission, reducing energy waste, meeting industrial energy-saving requirements, and lowering operating costs.

3.Controllable Temperature Rise and Strong Heat Dissipation:

The reasonable heat dissipation structure and good heat-conducting materials enable rapid heat dissipation during operation. It effectively controls the temperature rise, prevents component damage due to overheating, ensures continuous and reliable work under high-temperature and heavy-load conditions, and guarantees the continuity of industrial production.

Product Applications

Frequency conversion, photovoltaic (solar power system), wind power generation, renewable energy, medical equipment, etc.