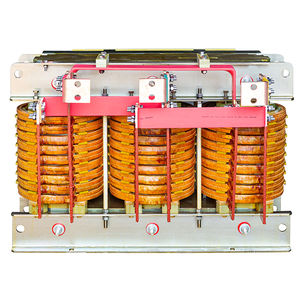

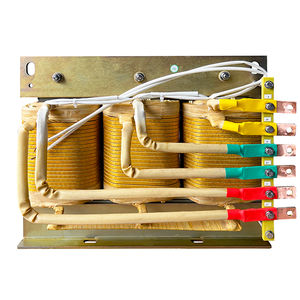

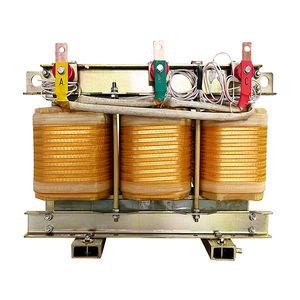

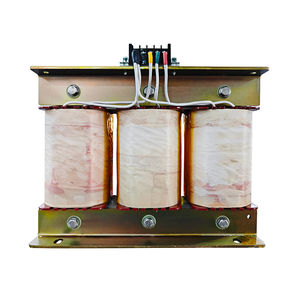

Power transformer SG-40K isolationdryfor industrial applications

Add to favorites

Compare this product

Characteristics

- Type

- power, isolation

- Configuration

- dry

- Applications

- for industrial applications

- Electrical characteristics

- three-phase, low-voltage

- Mounting

- floor-standing, quick-connect

- Norms

- IEC, EN61558, RoHS, Tier 2 EU

- Other characteristics

- reduction, variable

- Output power kVA

40 kVA

(54.384846 hp)- Primary voltage

560 V

- Secondary voltage

380 V

- Frequency

50 Hz, 60 Hz

Description

Product Overview:

Used in industry, this transformer isolates and steps down voltage. It ensures safe supply, suits loads, optimizes distribution, enhancing system reliability and efficiency.

Specific Introduction:

1. Vacuum Impregnation, Better Insulation

With vacuum impregnation, insulating paint fills the winding evenly. It boosts insulation, prevents short-circuits from moisture and dust, adapts to the industrial environment, resists impacts, and ensures stable long-term operation.

2. Multiple Taps, Flexible Conversion

The multiple taps allow flexible output voltage adjustment. It meets different equipment's voltage needs in industrial production without extra complex devices. It enables convenient power conversion, improves resource utilization, and cuts equipment costs.

3. High Efficiency, Cost Reduction

Advanced materials and design reduce operation losses. It consumes less energy and requires less heat dissipation. It saves energy, eases the cooling system's burden, and lowers industrial production costs, meeting the demand for efficient and sustainable development.

Operation Environment

A) Altitude: Not exceeding 1000m, shall be derating used if above 1000m;

B) Ambient Temperature: -25℃~55℃.

C) Relative Humidity: ≤95%;

D) As to the installation site, to make sure no bad effect on transformer insulation, chemical deposition, dust, and other explosive or erosive medium.

E) The supply voltage approximates sinusoidal wave, and the three-phase voltage is relatively balanced.

Related Searches

- Transformer

- Dry transformer

- Current transformer

- Encapsulated transformer

- Power transformer

- IEC transformer

- Single-phase transformer

- Isolation transformer

- Industrial transformer

- Three-phase transformer

- Low-voltage transformer

- Floor-standing transformer

- Instrument transformer

- Cast resin transformer

- Distribution transformer

- DIN rail mount transformer

- Transformer for industrial applications

- Protection transformer

- Toroidal transformer

- Choke coil

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.