- Packing - Handling - Logistics

- Conveying

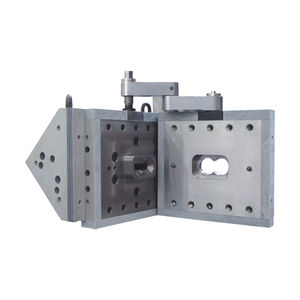

- 2-way diverter valve

- Maag Germany GmbH

Polymer melt diverter valve BiPoDVbidirectional

Add to favorites

Compare this product

Characteristics

- Applications

- for polymer melts

- Other characteristics

- bidirectional

Description

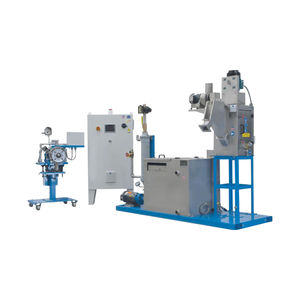

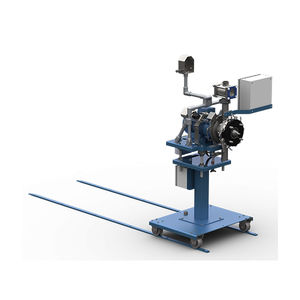

With the bidirectional polymer diverter valve (Model BiPoDV), the melt is diverted sequentially into different directions during the production process. This means that, depending on the requirements of the job, the machine operator can work with two pelletizing heads that can be individually configured. The operator can prepare the underwater pelletizing machine for the next task and assemble, heat, and tighten the ideal pelletizing tools under full production conditions. All connecting channels are freely accessible so the most recently used channels can be thoroughly cleaned. For product change, the polymer diverter valve housing is rotated and lifted into the new production position so melt flow is directed to the new fully prepared tool. The change of melt direction for the next production job can be readied in very little time and without tools. A lift-and-rotate mechanism makes it possible to change to a fully prepared and heated die plate at the operative machine within minutes.

Catalogs

No catalogs are available for this product.

See all of Maag Germany GmbH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.