- Metrology - Laboratory

- Metrology and Test Equipment

- Stationary thickness gauge

- Mabri.Vision GmbH Technologiezentrum am Europaplatz

Stationary thickness gauge INLINE.SECTOR F1wallfor plastic pipenon-contact

Add to favorites

Compare this product

Characteristics

- Type

- stationary

- Applications

- wall, for plastic pipe

- Technology

- non-contact

- Measuring range

Max.: 4 mm

(0.16 in)Min.: 0.1 mm

(0 in)

Description

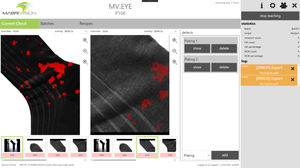

Inline hose wall thickness testing system INLINE.SECTOR F1

The future of tube inspection.

The MABRI.VISION INLINE.SECTOR F1 inspection system describes the future of quality control of plastic and silicone tubes: non-destructive and in the production cycle.

Efficient and on the move.

A 360 ° sensor creates cross-sections to inspect the inside and outside diameter, wall thickness and geometry of semi-transparent tubes: directly in your extrusion line.

Innovation - our passion!

Inspection processes must be perfectly integrated into production processes. MABRI.VISION therefore relies on innovative solutions to support your inspection process.

Your advantage.

Save material.

The MABRI.VISION inspection system INLINE.SECTOR F1 carries out the tube inspection continuously and non-destructively. In this way, you can maintain reliable tolerances throughout and reduce your material consumption.

Start up production faster.

Continuous inspecting enables the INLINE.SECTOR F1 to accelerate the setting of the production system. In this way you avoid initial error reports and gain production time.

100% quality certificate.

Achieve a holistic inspection of your products. The 100% inspection with a certified inspection system can help accelerate the certification of your production products.

Check inline.

The INLINE.SECTOR F1 checks tubes for applications with the highest demands directly in your extrusion line. The non-contact measuring method enables, among other things, the inspection of wall thickness, shape and misalignment.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Mabri.Vision GmbH Technologiezentrum am Europaplatz‘s catalogsOther Mabri.Vision GmbH Technologiezentrum am Europaplatz products

Products

Related Searches

- Measuring machine

- Thickness measuring machine

- Optical measuring machine

- High-precision measuring machine

- 3D measuring machine

- Stationary thickness measuring machine

- Precision thickness measuring machine

- Vision measuring machine

- Wall thickness measuring machine

- 2D measuring machine

- Coordinate measurement system

- Material thickness gauge

- Pipe thickness measuring machine

- Non-contact thickness measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.