- Metrology - Laboratory

- Inspection and Monitoring

- 3D inspection system

- Mabri.Vision GmbH Technologiezentrum am Europaplatz

3D inspection system MV.EYE CR1confocalmeasurementsurface

Add to favorites

Compare this product

Characteristics

- Technology

- 3D, confocal

- Type

- measurement, surface

- Applications

- for the pharmaceutical industry

Description

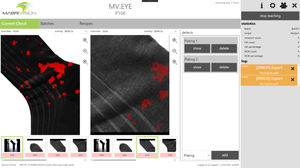

High-precision 3D surface inspection system MV.EYE CR1

The MV.EYE CR1 inspection system enables the surfaces of products and components to be scanned quickly and with great precision using a 3D chromatic confocal line sensor. With 192 measuring points in a line and a measuring frequency of up to 6,000 Hz, even larger inspection areas with a very high point density can be scanned quickly. Inspection processes that take up to several hours with classic confocal point sensors can be implemented in minutes with the new MV.EYE CR1 inspection system.

3D surface inspection with 20nm resolution

The fields of application range from the surface inspection and shape inspection of wafers, the defect inspection and roughness inspection on metal parts or shape inspection of precise injection molded components to the gap measurement in assembly processes of premium products. If the z-measuring range of the sensor is not sufficient, it can be expanded almost at will by moving the sensor vertically.

The inspection system for automated production processes

Previous inspection processes with point sensors can be reduced from hours to minutes with the new MV.EYEC CR1 platform. The generated 3D surface data achieve a resolution of 20 nm in z. Thanks to an intelligent and modular combination of different high-performance optics, a wide range of inspections can be carried out, making the inspection system a reliable complete solution in various areas of application.

Catalogs

No catalogs are available for this product.

See all of Mabri.Vision GmbH Technologiezentrum am Europaplatz‘s catalogsOther Mabri.Vision GmbH Technologiezentrum am Europaplatz products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.