- Metrology - Laboratory

- Metrology and Test Equipment

- Coordinate measuring system

- Mabri.Vision GmbH Technologiezentrum am Europaplatz

Coordinate measuring system MV.EYE i2 WTopticalvision3D

Add to favorites

Compare this product

Characteristics

- Measured physical value

- coordinate

- Technology

- optical, vision, 3D, 2D

- Other characteristics

- high-precision

Description

Inline 2D/3D measurement

on the goods carrier MV.EYE i2 WT

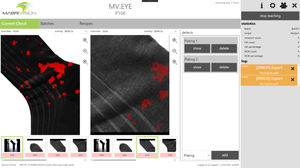

With the MV.EYE i2 WT inspection system, MABRI.VISION offers an inline-capable vision solution for seamless quality inspections in your production line. The inspection system enables contactless inspections of 2D and 3D component features and can be seamlessly integrated into the system environment using common industrial interfaces. Special properties of the inspection system are the high speed of the inspection processes, which enables inspections within the production cycle, as well as the modular system structure.

Contactless 100% production control in the production cycle

With the MV.EYE i2 WT inspection system, MABRI.VISION offers an inline-capable vision solution for seamless quality inspection in your production line. The inspection system enables contactless inspections of 2D and 3D component features and can be seamlessly integrated into the system environment using common industrial interfaces. Special properties of the inspection system are the high speed of the inspection processes, which enables inspections in the production cycle, as well as the modular system structure. When designing the inspection system, the MABRI.VISION experts rely on the latest technologies. A 100% inspection of your components is implemented through the combination of a 3D surface inspection, a large-area telecentric 2D inspection and a 2D & 3D inspection with an optical micrometer. The special feature of the combination of different inspection sensors is that the inspections are not only viewed independently of one another. The transfer to a common coordinate system enables high-precision results to be delivered.

Catalogs

No catalogs are available for this product.

See all of Mabri.Vision GmbH Technologiezentrum am Europaplatz‘s catalogsOther Mabri.Vision GmbH Technologiezentrum am Europaplatz products

Products

Related Searches

- Measuring machine

- Thickness measuring machine

- Optical measuring machine

- High-precision measuring machine

- 3D measuring machine

- Stationary thickness measuring machine

- Precision thickness measuring machine

- Vision measuring machine

- Wall thickness measuring machine

- 2D measuring machine

- Coordinate measurement system

- Material thickness gauge

- Pipe thickness measuring machine

- Non-contact thickness measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.