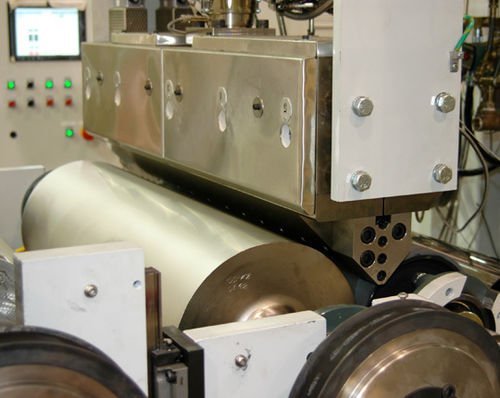

Macro's PVdC extrusion coating line is an affordable alternative for coating different substrates with PVdC. One of the greatest benefits of the line is that desired coating weight is obtained in one pass, delivering a PVdC layer that is pinhole free and impervious to flex cracking.

Unlike conventional PVdC water dispersion systems that require multiple passes to obtain the desired coating weights, Macro's PVdC extrusion coating line does not limit the barrier thickness. It also has low process costs and requires significantly lower capital investment.

Given the outstanding moisture and oxygen barrier properties of PVdC, the extrusion coating process can be used in medical, pharmaceutical and food packaging applications. Typical substrates that can be coated include PVC, PE and paper.

Features

PVDC coating thickness from 20 microns (34 gsm) to 250 microns (425 gsm)

Coating speeds up to 50 m/min based on coating weight

Thickness of PVC sheeting to be coated from 80 microns to 350 microns

Width up to 1200 mm before trimming

Benefits

Coating weights achieved in a single pass

Higher coating weights possible unlike conventional systems

Superior flex crack resistance of PVDC coating compared to conventional systems

Improved moisture and oxygen barrier properties

Lower capital investment and operating costs

Finished product meets new pharmaceutical packaging standards

Superior vacuum forming performance compared to PVDC dispersion coating