- Products

- Catalogs

- News & Trends

- Exhibitions

SMT pick-and-place machine SX1000 Seriesautomatic

Add to favorites

Compare this product

Characteristics

- Applications

- SMT

- Other characteristics

- automatic

Description

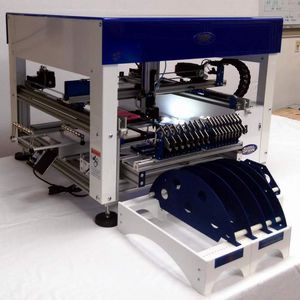

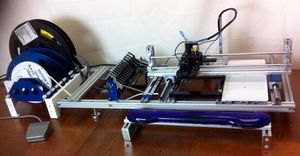

SX1000 Series Office Automatic Pick and Place Machines with Computer Vision Centering

The SX series mini automatic pick and place machines are specially designed for low budget circuit boards assembling. It is a great tool for prototypes, education and research, as well as small batch of production.

Quick tape mounting with our innovated tape forwarding system (patent pending)

Full computer vision for small parts and fine pitch IC's

Fast and easy to use

Very low cost feeders

Features:

Place speed 2000 pph with SX-2 feeders when computer vision is enabled; 2500 with fly vision; 3000 with PX feeders

Placement of 0201 and bigger parts

Computer vision automatic centering system for IC's (SOP, QFP, BGA) and better placement of small parts

Smart Vision: no need of reference or template pictures for most SMT parts; IC is centered as a whole part and also based on pins. Accurate and easy to use

180W brushless servo motors and 4000 line encoders for X and Y axes

X, Y axis resolution 0.00025", 0.045° rotational resolution

Max. feeder capacity: 60 SX-2 8mm feeders for SX1010 and SX2010(feeders mounted at front, rear and middle); 150 SX-2 8mm feeders for SX1020; Vibration feeders and trays take tape feeder space

Free feeders: twenty SX-2 8mm paper or plastic tape feeders included for SX1010 and SX2010, forty included for SX1020

Low cost additional feeders

Automatic PCB board position correction with fiducial recognition included

CAD file convert function

VIDEO

Catalogs

No catalogs are available for this product.

See all of Madell Technology‘s catalogsRelated Searches

- Stencil printer

- Automatic stencil printer

- Soldering machine

- Reflow soldering machine

- Pick-and-place system

- Flat bed stencil printer

- Rework station

- Printed circuit soldering machine

- SMT pick-and-place system

- Electronic stencil printer

- Automatic pick-and-place system

- SMT stencil printer

- Solder paste stencil printer

- Hot air rework station

- Automatic rework station

- BGA rework station

- Metal hot plate

- Aluminium hot plate

- Manual stencil printer

- Solder bath

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.