- Production Machines

- Forming Machine

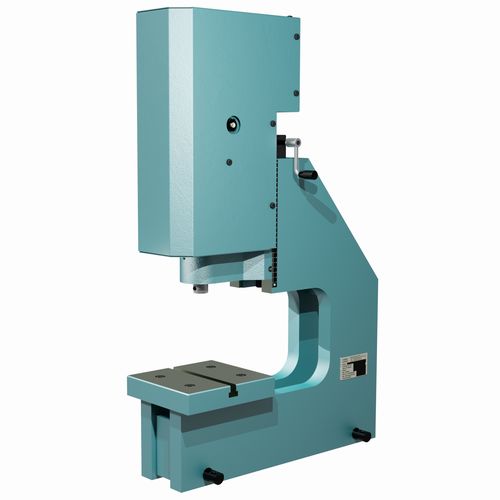

- Pneumatic press

- mäder Pressen

Pneumatic press XL-APK 5 Lpunchingrivetingfor gluing

Add to favorites

Compare this product

Characteristics

- Operation

- pneumatic

- Function

- stamping, punching, riveting, for gluing

- Structure

- ram, toggle, round ram

- Other characteristics

- fixed, economical

- Force

32 kN

- Stroke

40 mm

(1.575 in)- Table width

190 mm

(7 in)- Table length

200 mm

(8 in)- Weight

150 kg

(331 lb)

Description

Throat [mm]: - 300

Troat [mm]: - 130

T-slot [mm] similar to DIN 650: - 14

Ram bore Øxdepth [mm]: - 12H7 x 30

Ram Ø [mm] / Surface F [mm²]: - 30

Space required CxG [mm]: - 200 x 385

mäder pneumatic toggle presses reach their naximum force at the end of the stroke, the bottom dead center (BDC). The optimum transmission ratios of the toggle press produce high force at the end of the stroke, ensuring low air consumption. Thanks to the resultant low energy consumption, mäder pneumatic toggle presses are an economical means of production not only at the time of purchase, but also in the long term.

Toggle presses are used when the full force of the press is only needed at the end of stroke, e.g. for punching, riveting, stamping, gluing etc.

All direct acting pneumatic presses are available as an automation module or can be supplied with mäder controls for individual workstations..

The round ram of mäder pressen is characterized by high sturdiness, ground surface and precise ram bore. Tools can be fixed securely in the ram bore by means of a fixation screw. Round rams of mäder pressen are either guided in precision honed bores or in precise Teflon bushings.

Quality features:

• - Factory pre-set pressure point

• - Right-angled gearbox for simple height adjustment of the press head

• - Side-mounted measuring strip for fast reproduction of settings when changing the tool

• - Practically maintenance-free double-acting cylinder

• - Low noise: less than 75 dB

Catalogs

No catalogs are available for this product.

See all of mäder Pressen‘s catalogsRelated Searches

- Mäder industrial press

- Hydraulic press

- Mäder forming press

- Mäder joining press

- Mäder vertical press

- Mäder punching press

- Mäder pneumatic press

- Mäder ram press

- Mäder manual press

- Mäder stamping press

- Mäder mechanical press

- Mäder production press

- Measurement monitoring device

- Mäder bending press

- C-frame press

- Compression press

- Compact press

- Mäder fixed press

- Mäder shop press

- Mäder hand-operated press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.