- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

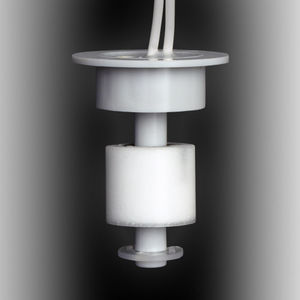

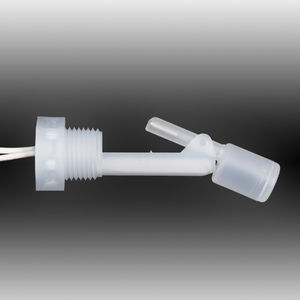

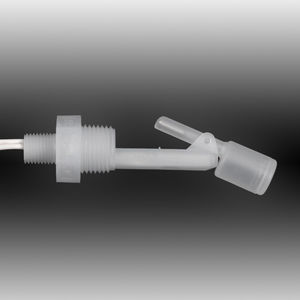

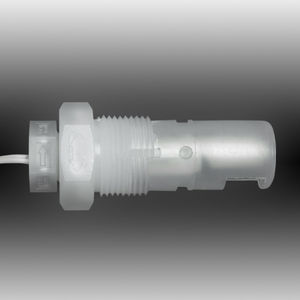

Float level sensor C4954-xxxxxliquid4-20 mAfor small tanks

Add to favorites

Compare this product

Characteristics

- Technology

- float

- Medium

- liquid

- Interface

- 4-20 mA

- Applications

- for small tanks, for OEM, rugged

- Other characteristics

- stainless steel, high-precision, miniature

- Level range

Min.: 3 in

Max.: 13 in

- Process temperature

Min.: -40 °C

(-40 °F)Max.: 105 °C

(221 °F)

Description

Accurate measurement of liquid volumes at any point in a container is critical for many commercial and industrial processes. Reducing process variability results in less waste, higher quality and reduced cost, and can make a big difference in profitability for OEMs.

Madison's continuous float level sensors offer all the advantages of reed switch based technology, now available in a ruggedized, miniature version for applications with a small tank footprint.

Madison’s miniature continuous float level sensors provide feedback that is used to achieve precise fluid level detection at any point in the tank. As part of a feedback loop, the linear sensor output can also be used to adjust metering pumps or flow valves to maintain predictable process control.

C4954-xxxxx Miniature Continuous Float Level Sensor Features:

Customizable mountings and sensing length from 3” to 13”

Proven, durable construction for harsh environments

Provides precise, linear, continuous liquid level values

Configurable in mixed materials for fluid compatibility and long life

Ideal for small dosing tanks

Provides standard 4-20mA, resistive or voltage output types for panel meters and PLCs

Much smaller ‘deadband’ than radar and ultrasonic sensors

Applications:

Dispensing fuel additives

Monitoring high value chemicals

Monitoring dispensed agricultural fertilizers

Small day tank level monitoring

Lubricating applications

Catalogs

No catalogs are available for this product.

See all of Madison Company‘s catalogsRelated Searches

- Level limit switch

- Level probe

- Liquid level limit switch

- Liquid level probe

- Analog level probe

- Protection level level switch

- Float level switch

- Stainless steel level limit switch

- Digital output level probe

- Threaded level limit switch

- Storage tank level probe

- Plastic level switch

- Magnetic float level switch

- Stainless steel level probe

- Water level probe

- Vertical level detector

- IP67 level probe

- Ultrasonic level sensor

- Radar level sensor

- Solid level probe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.