- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Welded pipe

- Magnetic Shield Corporation

- Products

- Catalogs

- News & Trends

- Exhibitions

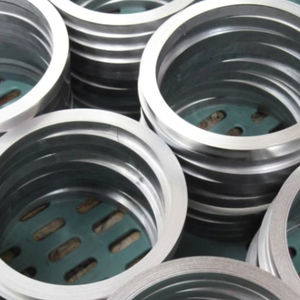

Custom pipe MuMETAL® Tubingweldedround

Add to favorites

Compare this product

Characteristics

- Other characteristics

- custom, welded, round

Description

MuMETAL® Tubing | Pipe

Availability:

Custom order to your specifications

Custom Sizes Available:

Specify your diameter / length ratio and design configuration. Select CUSTOM Size option below. Please allow 3-5 weeks for custom MuMETAL® Tubing | Pipe

DESCRIPTION

Custom MuMETAL® Tubing | Pipe can be CNC machined from our stock MuMETAL® Round Bar producing hundreds to thousands of precision tubes for micro-assemblies. Our MuMETAL® Round Bar is stocked in diameters from 0.25 in to 8.17 in / 6,35 mm to 207,5 mm and is available for purchase. It is critical however that all CNC machined parts are Perfection Annealed after machining to attain maximum shielding performance.

If you require longer tubes or pipe with a 4:1 length-diameter ratio, it may be more cost effective to have Magnetic Shield Corporation fabricate to your drawing or specification using our MuMETAL® Stress Annealed Sheet to roll-form or press-form your tube profile. Tubing | Pipe seams are TIG welded on mandrel tooling to avoid slag or burrs interior to the tube. Again, atmospherically controlled Perfection Annealing is necessary for all fabricated Tubing | Pipe.

Typically, we can prototype most tubes or pipe in 3 weeks using our stock tooling. Ask about our precise prototyping capability, model shop volume and high-volume production capacity.

Our MuMETAL® Tubing | Pipe is not pressure tested for hazardous liquid or gas transmission. To ease installation complexities, shield tubes may be designed in linear sections or split in half sections connected with bead-rolled overlapping joints.

Catalogs

No catalogs are available for this product.

See all of Magnetic Shield Corporation‘s catalogsOther Magnetic Shield Corporation products

MuMETAL® Brand Products

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.