- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

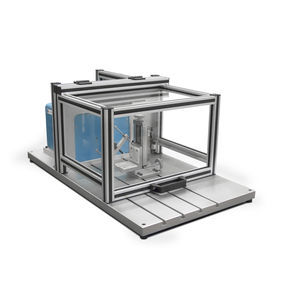

Hysteresis brake HD seriesmechanicalmanualdynamometer

Add to favorites

Compare this product

Characteristics

- Type

- hysteresis

- Operation

- mechanical, manual

- Other characteristics

- dynamometer

- Rotational speed

Min.: 8,000 rpm

(50,265.48 rad.min-1)Max.: 30,000 rpm

(188,495.56 rad.min-1)- Power

Min.: 7 W

Max.: 300 W

Description

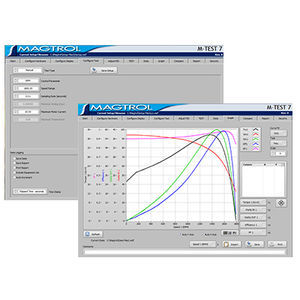

The most important characteristic of any measurement instrument is repeatability and accuracy. The Magtrol Dial Weight Dynamometer uses the combination of a Hysteresis Brake and gravity to insure constant, reliable results. The brake torque rise is directly proportional to applied current. The calibrated weight system provides readings in standard engineering units through the use of multiple torque range scales provided on each size dynamometer.

Magtrol Dial Weight Dynamometers are a lower cost alternative to our standard (load cell) Hysteresis Dynamometers. The dial weight dynamometers are easy to operate, provide repeatable and accurate results, and will operate for many years with minimal maintenance. A Magtrol Dial Weight Dynamometer System can only operate manually in an open loop mode.

Features

Models as low as 0.5 oz·in full scale to 200 lb·in Full scale. Each dial weight dynamometer comes with three weights to cover the three specified ranges.

Metric scales are also available. Magtrol Dynamometers are certified to Mil-STD 45662A and are NIST traceable.

Load can be adjusted from no load to full scale through simple potentiometer control on power supply.

Magnetically coupled hysteresis brake provides smooth torque application independent of shaft speed. This permits testing motors from no load to locked rotor or armature.

Dynamometer Selection

Magtrol Dynamometers cover a wide range of Torque, Speed and Mechanical Power ratings. To select the appropriate size Dynamometer for your motor testing needs, you will need to determine the Maximum Torque, Speed and Power applied to the Dynamometer:

Catalogs

Related Searches

- Flexible shaft coupling

- Shafts coupling

- Flange shaft coupling

- Torque shaft coupling

- MAGTROL electromagnetic brake

- Transmission shaft coupling

- Compact shaft coupling

- Misalignment correction shaft coupling

- Electromagnetic clutch

- Custom-made coupling

- Compensating shaft coupling

- Anti-vibration shaft coupling

- Metal bellows shaft coupling

- Clutch and brake

- Double shaft coupling

- Torsionally flexible shaft coupling

- Stainless steel shaft coupling

- Manual brake

- MAGTROL motor brake

- Mechanical brake

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.