- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

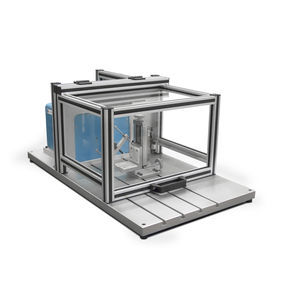

Mechanical alignment tool ATK-25shaft

Add to favorites

Compare this product

Characteristics

- Technology

- mechanical

- Applications

- shaft

Description

The ATK-25 is a unique shaft alignment solution, specially designed for small equipment. The ATK can be used to measure parallel and angular alignment, for correction of pitch, yaw, vertical, and horizontal positioning. It works in crowded or constrained locations where other tools will not fit.

Alignment is critical for rotating equipment. Poor alignment can cause:

Excessive Vibration: Misaligned shafts lead to higher vibrations, which can result in mechanical failure or decreased performance

Increased Wear and Tear: Bearings, seals, and couplings can experience premature wear due to the

additional forces exerted by misaligned shafts

Equipment Failure: Continuous operation with misaligned shafts can lead to mechanical failure,

resulting in costly repairs and downtime

Reduced Quality: In many industries, precision machinery is critical to maintaining product quality

Proper alignment tools and techniques provide major benefits, and are essential to achieving:

Smooth operation, with the lowest noise and highest performance

Long lifespan of component parts and minimum maintenance costs

Reliable Operation, with the minimum downtime

High production quality

Motor testing also requires good shaft alignment to produce the most accurate and consistent results. Unfortunately, the shaft alignment solutions widely available are not designed for use with smaller equipment.

Catalogs

No catalogs are available for this product.

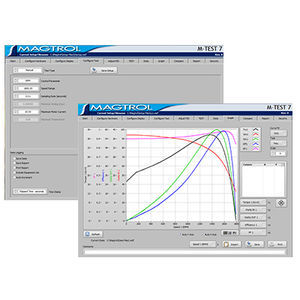

See all of MAGTROL‘s catalogsRelated Searches

- Measuring device

- MAGTROL test bench

- MAGTROL automatic test bench

- Digital measuring device

- Industrial gauge

- MAGTROL industrial test bench

- MAGTROL computer-controlled test bench

- Test set

- Automatic measuring device

- Benchtop measuring device

- MAGTROL manual test bench

- Laboratory measuring device

- High-precision measuring device

- Vertical test stand

- Voltage measuring device

- MAGTROL test bench for the automotive industry

- Extensometer

- USB measuring device

- MAGTROL horizontal test bench

- Electronic measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.