- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Monitoring control system Optipac VMC-15processautomationmeasurement

Add to favorites

Compare this product

Characteristics

- Function

- monitoring, process, automation, measurement, regulating, humidity, temperature

- Type/technology

- digital

- Product applications

- for drying ovens

- Other characteristics

- automatic, online

Description

Modular process control system

Optipac VMC - Process control for textile finishing

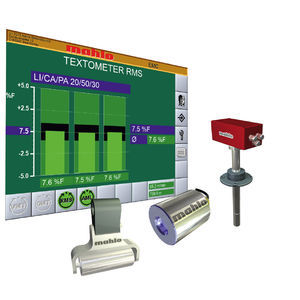

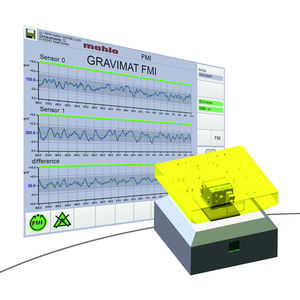

The versatile process control for textile drying and finishing convinces with simple and ergonomic software as well as a multitude of sensors.

OPTIMIZES FINISHING

The Orthopac VMC is a modular process control system for textile refinement. It optimises drying or fixing processes as well as the processes all about the stenter. The system measures, logs and controls critical process parameters over the entire working width like temperature, dwell time, residual moisture, exhaust air moisture, thread density, basis weight and more. This increases quality while saving resources and energy.

The modular design of the system allows its flexible adaptation to all applications. Both, standard requirements and highly customized demands are thus met.

The system can also be integrated into an Orthopac straightening system. It thereby combines the functionality of a weft straightener with that of a process control system in one compact device.

PRODUCT HIGHLIGHTS

• Modular system architecture

• Operator-friendly

• Informative process visualisation

• Online monitoring and control of all relevant parameters

• Easy to retrofit

CUSTOMER BENEFITS

• Increased productivity

• Optimised production security

• Increased process reproducibility

• Documentation and comparability of quality

• Considerable energy savings

• Short amortisation times

Catalogs

Optipac VMC-15

32 Pages

Related Searches

- Industrial control system

- Monitoring control system

- Digital control system

- Automatic control system

- Process control system

- Quality control system

- Electric control system

- Automation control system

- Temperature regulator control system

- Temperature control system

- Measurement control system

- Weighing controller

- In-line control system

- Non-destructive control system

- Computer-controlled control system

- Regulating control system

- Non-contact control system

- Humidity control system

- LED control system

- Laser control system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.