- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Relative humidity sensor Ecosense ZS-12insertionair

Add to favorites

Compare this product

Characteristics

- Type

- relative

- Mounting

- insertion

- Applications

- air

Description

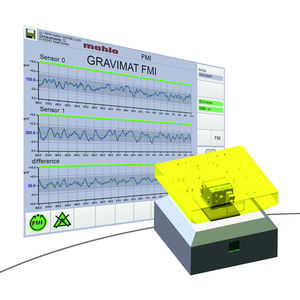

Sensor Ecomat AML

The exhaust air humidity sensor measures the proportions of oxygen, water vapour and harmful gases in the stenter frame.

MEASUREMENT OF STEAM

Much unused energy is wasted through the exhaust air during drying processes without appropriate control. The Ecomat AML optimises the heating energy required by monitoring charging of the exhaust air with water steam and controls this factor through the fan speed or the exhaust air vent control.

PRODUCT HIGHLIGHTS

• Highly accurate measurements

• Unaffected by carrier gases

• Measures oxygen, water vapour and harmful gas proportion

CUSTOMER BENEFITS

• Optimises energy balance

• Saves energy

• Increases process repeatability

Optimises energy balance

Saves energy

Increases process repeatability

Large amounts of hot air are used to permanently evaporate new water (humidity), thus transporting the resulting mixture of hot air and water vapour out of the dryer. This mixing ratio is very important for the economy of the entire drying process.

The amount of water to be evaporated during any period of time depends on the product weight, incoming and residual moisture, product width and transport speed. A constant fan speed or exhaust air flap position is not economic. The exhaust air humidity needs to be constantly measured and the setting of the fan speed or exhaust air flap setting automatically regulated.

Catalogs

No catalogs are available for this product.

See all of Mahlo‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.