- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

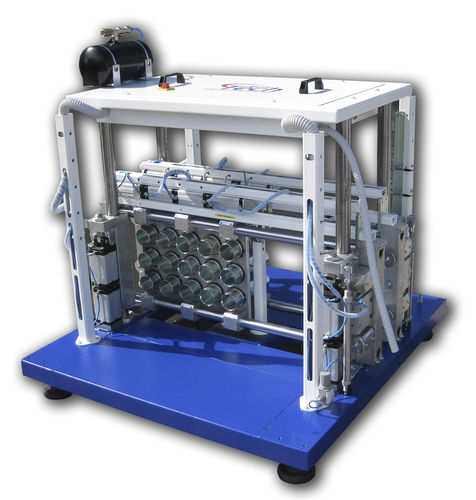

Automatic sorting and distribution system

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

Description

automatic sorting materials station 15x15 - 25x25 - 35x35 stations

from storage areas - silos to working areas

The new sorting material unit has been planned to create an automatic connection between the pipes loading station presses and the pipes of the various materials coming from storage areas.

It allows the distribution of more materials from the storage areas up to the presses guaranteeing the absolute absence of pollution between materials, and with the identification of the same according to the set program.

The distribution unit with Touch Sys system is a very flexible unit that allows the distribution of multiple materials to multiple machines using an electro-pneumatic system with Cartesian axes.

The heart of system is the central element of communication(electropneumatic collector)double sectors with gasketed tested for a perfect seal with the trade of pushing force on the two sides of input and output of materials.

The collector has been made for not having any stagnation of grain between changing of stations/materials, its position on the central part let it off from any contamination between one aspiration and the other.

It's equipped by air compressed automatic cleaning, which is activated in the final stage of the cleaning conduit cycle: in order to ensure total absence of micro dust that may become stagnant.

The simplicity of components and of the type of chosen activations, ensure reliability and precision over time without causing unpleasant machine stops and total absence of lubricant.

Catalogs

No catalogs are available for this product.

See all of MAIN TECH S.r.l.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.