- Machine-tools

- Machining Center

- 5-axis machining center

- MAKINO Milling Machine

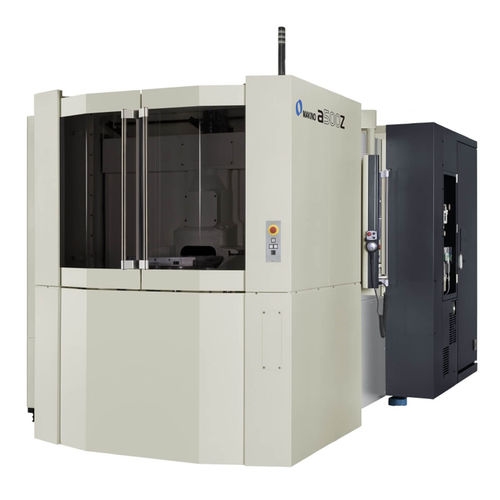

5-axis CNC machining center a500Zhorizontalwith rotary tableBT 40

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Structure

- with rotary table

- Spindle mount

- BT 40, HSK A-63

- Number of tool stations

- 60 tools

- Associated functions

- cutting

- Other characteristics

- high-speed, high-performance, direct-drive, high-power, with automatic tool changer

- X travel

730 mm

(28.74 in)- Y travel

750 mm

(29.53 in)- Z travel

Max.: 700 mm

(27.56 in)Min.: 500 mm

(19.69 in)- Rotational speed

14,000 rpm, 20,000 rpm

(87,965 rad.min-1, 125,664 rad.min-1)- Power

37 kW

(50.31 hp)- Work feed X-axis

50,000 mm/min

(33 in/s)- Work feed Y-axis

50,000 mm/min

(33 in/s)- Work feed Z-axis

50,000 mm/min

(33 in/s)- Table load capacity

400 kg

(882 lb)- Tool weight (max)

12 kg

(26.5 lb)- Tool-changing time

0.9 s

Description

This versatile machine builds upon the industry leading performance and reliability of our nx-series four axis HMC’s, adding a factory built and fully integrated “Z-type” fifth axis to accommodate today’s more complex part geometry challenges in a minimum number of workholding setups and machining operations.

The unique kinematic arrangement of the a500Z minimizes the force path lengths both through the spindle as well as through the workpiece, efficiently transferring both cutting loads and reactive forces into the machine’s three point leveled bed, maximizing both metal removal rates and perishable tool life due to unparalleled system rigidity.

The a500Z accommodates workpieces of up to Ø630mm x 500mm high, with payload weights up to 400kg. The X- and Y- strokes are 730mm and 750mm respectively, with the Z- stroke ranging from 500mm – 700mm, depending on the rotary axes positioning. Both rotary tables are of the direct drive type, with unlimited 360° movement on the B-, and 180° on the innovative ‘slant style’ C-axis unit. This allows a full range of workpiece positioning ranging from the pallet top sitting horizontal to the spindle centerline to parallel to the spindle centerline, or anywhere in between these two extremes. As has long been Makino’s hallmark, all axes on the a500Z have closed loop active temperature control standard, providing not only the superior dimensional control that is inherent to this design, but also extended component life even in the most demanding production environments.

Catalogs

No catalogs are available for this product.

See all of MAKINO Milling Machine‘s catalogsOther MAKINO Milling Machine products

5‑Axis Horizontal Machining Centers

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

- CNC machining center with pallet changer

- Horizontal CNC machining center

- BT 40 CNC machining center

- Compact CNC machining center

- EDM

- Machining center for the automobile industry

- Direct-drive CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.