- Machine-tools

- Machining Center

- 5-axis machining center

- MAKINO Milling Machine

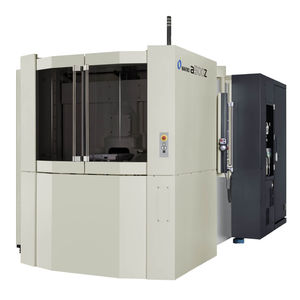

5-axis CNC machining center a51nx-5XUhorizontalfor the aerospace industryfor medical applications

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Applications

- for the aerospace industry, for medical applications

- Other characteristics

- high-performance, high-productivity, direct-drive

- X travel

580 mm

(22.83 in)- Y travel

640 mm

(25.2 in)- Z travel

500 mm

(19.69 in)- Rotational speed

14,000 rpm, 20,000 rpm

(87,965 rad.min-1, 125,664 rad.min-1)- Work feed X-axis

50,000 mm/min

(33 in/s)- Work feed Y-axis

50,000 mm/min

(33 in/s)- Work feed Z-axis

50,000 mm/min

(33 in/s)- Table load capacity

30 kg

(66 lb)- Tool weight (max)

12 kg

(26.5 lb)- Tool-changing time

0.9 s

Description

Manufacturers of medical, aerospace, prototype and complex multi-face parts have long understood the advantages of 5-axis machining. Five-axis machining capability can improve productivity and quality simply by consolidating operations.

The linear X-, Y- and Z-axes of the a51nx-5XU are built from the same tiered column, bed and rigid casting structure as Makino’s industry-leading a51nx. Rotary B- and C-axis motion comes from a pair of responsive (75 / 150 rpm) direct-drive motors. Both motors are housed in an integral cast structure that eliminates the stack-up errors and loss of rigidity common with table-on-table 5-axis designs. The contoured table casting provides ideal spindle accessibility to the workpiece. The C-axis cables are routed through the splash-guard ceiling, ensuring reliability and chip-free operation.

What makes the a51nx-5XU stand apart from other small 5-axis machining solutions is its horizontal orientation and integrated workpiece automation. Horizontal orientation offers ideal chip shedding. Avoiding recutting of chips, especially in aerospace and medical materials, improves tool life and part surface finish. Loading parts in a 5-axis horizontal orientation, however, can lead to some material-handling challenges. The a51nx-5XU eliminates these challenges with its unique work-pallet magazine.

Each a51nx-5XU is configured with a work-pallet magazine (WPM) similar to Makino’s proven matrix tool magazines. The standard WPM22 stores 22 workpieces up to ᴓ300mm wide by 300mm tall. An optional WPM58 can hold 58 smaller ᴓ200mm parts. Parts are mounted directly to 50-taper dual-contact tool holders (BBT50) and stored in the WPM matrix.

Catalogs

No catalogs are available for this product.

See all of MAKINO Milling Machine‘s catalogsOther MAKINO Milling Machine products

5‑Axis Horizontal Machining Centers

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

- CNC machining center with pallet changer

- Horizontal CNC machining center

- BT 40 CNC machining center

- Compact CNC machining center

- EDM

- Machining center for the automobile industry

- Direct-drive CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.