- Machine-tools

- Machining Center

- 5-axis machining center

- MAKINO Milling Machine

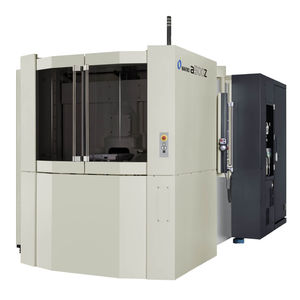

5-axis CNC machining center MAG1horizontalfor aluminum120 tools

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Machined material

- for aluminum

- Number of tool stations

- 120 tools

- Applications

- for the aerospace industry

- Other characteristics

- high-productivity

- X travel

1,520 mm

(59.84 in)- Y travel

1,100 mm

(43.31 in)- Z travel

1,350 mm

(53.15 in)- Rotational speed

33,000 rpm

(207,345 rad.min-1)- Power

120 kW

(163.15 hp)- Work feed X-axis

50,000 mm/min

(33 in/s)- Work feed Y-axis

50,000 mm/min

(33 in/s)- Work feed Z-axis

50,000 mm/min

(33 in/s)- Table load capacity

1,300 kg

(2,866 lb)- Tool weight (max)

8 kg

(17.6 lb)- Tool-changing time

17 s

Description

Ideally suited for high-productivity machining of aluminum monolithic aerospace parts under 1.5M.

The MAG1 integrates speed and power of the spindle with a machine platform that provides rapid precision-contouring capability while maximizing the percentage of in the cut spindle time. Five face accessibility to the work piece minimizes setups and process variation.

Industry-leading 33,000 rpm – 120kW spindle design, ensures high metal-removal rates. The MAG1 can also be integrated with an automatic pallet transfer and storage system in Makino’s highly flexible MMC system that enables extended periods of unattended operation.

Catalogs

No catalogs are available for this product.

See all of MAKINO Milling Machine‘s catalogsOther MAKINO Milling Machine products

5‑Axis Horizontal Machining Centers

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

- CNC machining center with pallet changer

- Horizontal CNC machining center

- BT 40 CNC machining center

- Compact CNC machining center

- EDM

- Machining center for the automobile industry

- Direct-drive CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.