- Machine-tools

- Machining Center

- 5-axis machining center

- MAKINO Milling Machine

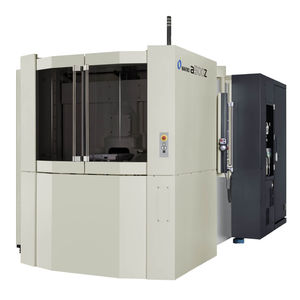

5-axis CNC machining center N2-5XAhorizontal36 toolscutting

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Number of tool stations

- 36 tools

- Associated functions

- cutting

- Applications

- for medical applications

- Other characteristics

- high-performance, direct-drive

- X travel

300 mm

(11.81 in)- Y travel

300 mm

(11.81 in)- Z travel

230 mm

(9.06 in)- Rotational speed

20,000 rpm

(125,664 rad.min-1)- Work feed X-axis

32,000 mm/min

(21 in/s)- Work feed Y-axis

32,000 mm/min

(21 in/s)- Work feed Z-axis

32,000 mm/min

(21 in/s)- Table load capacity

30 kg

(66 lb)- Tool weight (max)

2 kg

(4.4 lb)- Tool-changing time

1.2 s

Description

Makino has launched the N2-5XA, a 5-axis horizontal machining centre engineered to revolutionise medical implant production. Its unique design avoids the use of water-based coolant by deploying a unique chip-less design of the machining chamber. Thanks to the Professional 6 NC control unit and the direct-drive rotary axes the N2-5XA is capable of producing components with the smoothest possible surfaces.

Sustainable performance

The N2-5XA is engineered to offer the best performance in its machine size category – without using cutting oil lubrication. Especially designed for use in the medical manufacturing industry, e.g. for femoral knee implants, the N2-5XA exceeds the quality demands for medical use and ensures sustainable performance. Without cutting oil lubrication and thus without coolant, the simplified machining process helps end-users to reduce tack times, which in return enables higher production quantities.

Full flexibility

Smooth surfaces are of utmost significance, particularly for medical implants. To deliver the surface finish the parts need, the N2-5XA is a 5-axis machining centre featuring a trunnion table equipped with direct-drive motors on both the B and C axes. The small trunnion structure and long rotary travels grant the flexibility to access any part from any position. And thus offer full flexibility, not only for implant production.

Reducing costs the environment-friendly way

The most demanding implants can be cut on the N2-5XA without cutting oil lubrication. By avoiding the use of coolant, this machine is more environment-friendly. Besides, not using coolant brings the additional benefit of cost savings in production additives.

Catalogs

No catalogs are available for this product.

See all of MAKINO Milling Machine‘s catalogsOther MAKINO Milling Machine products

5‑Axis Horizontal Machining Centers

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

- CNC machining center with pallet changer

- Horizontal CNC machining center

- BT 40 CNC machining center

- Compact CNC machining center

- EDM

- Machining center for the automobile industry

- Direct-drive CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.