- Machine-tools

- Machining Center

- 3-axis machining center

- MAKINO Milling Machine

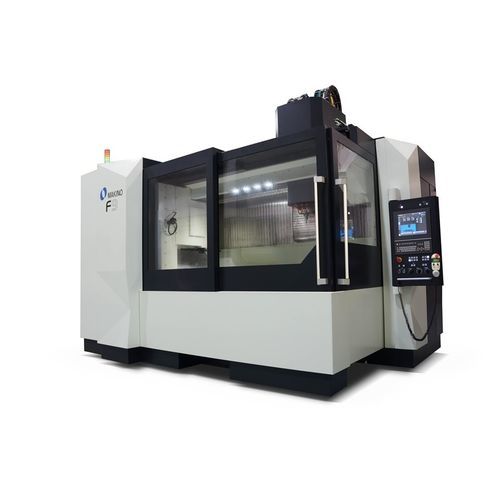

3-axis CNC machining center F9verticalCAT50HSK-A 100

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Spindle mount

- CAT50, HSK-A 100

- Number of tool stations

- 30 tools

- Associated functions

- milling, cutting

- Other characteristics

- high-speed, high-power, high-precision

- X travel

1,600 mm

(62.99 in)- Y travel

800 mm

(31.5 in)- Z travel

650 mm

(25.59 in)- Work feed X-axis

24,000 mm/min

(16 in/s)- Work feed Y-axis

24,000 mm/min

(16 in/s)- Work feed Z-axis

24,000 mm/min

(16 in/s)- Table load capacity

2,500 kg

(5,512 lb)- Tool weight (max)

20 kg

(44.1 lb)

Description

The F9 is designed to to attack both large production part applications as well as big die and mold components by provide stiffness and rigidity for chatter-free, heavy cutting, roughing and finishing on the same machine, agility for high-speed / hard-milling and accuracies for tight-tolerance blends and matches typical of complex, 3-D contoured geometry associated with die/mold and medical production. The unique machine design provides unparalleled access to ease setup and changeover reducing WIP and overall lead-time.

The F9 is designed to provide stiffness and rigidity for chatter-free, heavy cutting, roughing and finishing on the same machine, agility for high-speed / hard-milling and accuracies for tight-tolerance blends and matches typical of complex, 3-D contoured geometry associated with die/mold and medical production.

The unique machine design provides unparalleled access to ease setup and changeover reducing WIP and overall lead-time.

Equipped with a 37 kW, 10,000 RPM, CAT50 (or an optional HSK – A100) spindle and a large workzone and heavy payload capacity, the F9 can be productive in virtually any segment of the large VMC market. Standardly equipped with scale feedback and core – cooled ballscrews, the machine controls thermal growth achieving greater accuracy for longer term production performance. With a 30 tool magazine, there is sufficient tooling capacity to support a wide variety of large part manufacturing.

Catalogs

No catalogs are available for this product.

See all of MAKINO Milling Machine‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Cutting CNC machining center

- Horizontal CNC machining center

- CNC machining center with pallet changer

- BT 40 CNC machining center

- EDM

- Compact CNC machining center

- Machining center for the automobile industry

- Turning-milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.