- Machine-tools

- Machining Center

- 3-axis machining center

- MAKINO Milling Machine

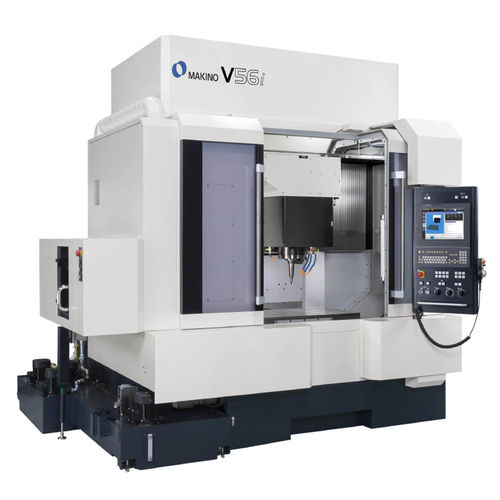

3-axis CNC machining center V56iverticalHSK A-63HSK F63

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Spindle mount

- HSK A-63, HSK F63

- Number of tool stations

- 40 tools, 60 tools

- Applications

- for molds

- Other characteristics

- high-speed, high-performance, compact, high-precision, high-rigidity

- X travel

900 mm

(35.43 in)- Y travel

550 mm

(21.65 in)- Z travel

450 mm

(17.72 in)- Rotational speed

20,000 rpm

(125,664 rad.min-1)- Work feed X-axis

20,000 mm/min

(13 in/s)- Work feed Y-axis

20,000 mm/min

(13 in/s)- Work feed Z-axis

20,000 mm/min

(13 in/s)- Table load capacity

800 kg

(1,764 lb)- Tool weight (max)

8 kg

(17.6 lb)- Tool-changing time

6.5 s

Description

The V56i vertical machining center provides high-speed machining with superb accuracy, efficient chip removal and ease of operation for long cycle time die/mold parts.

The machine is equipped with core-cooled ballscrews, support bearings and motor mounts as well as a core-cooled saddle design with Nano slideway to control machine thermal growth, providing sustained accuracy in long cycle time, complex geometry die/mold work.

The spindle features Makino’s unique, patented, core-cooling and under-race lubrication system, minimizing thermal distortion at high spindle speeds. Integrated construction of the spindle and drive motor rotor reduces vibration during high-speed operation. The V56i’s optimum axis layout and machine construction give you superior performance in a compact package. The axis layout is designed with no overhangs to ensure outstanding accuracy over the full range of axis travel. Painstakingly polished to a precision finish, the guideways are integrated with the machine to provide superior accuracy and rigidity.

The V56i vertical machining center incorporates a number of design features specifically designed to increase precision and maintain it for the long periods of time typical of most die and mold applications. With X- and Z-axes on the spindle and Y-axis under the table, the machine construction provides superior performance in a compact package. Designed with no overhangs or unsupported areas, the V56i delivers outstanding accuracy over the full range of machine. Painstakingly polished to a precision finish, the guideways are integral to the machine castings to provide superior stiffness, rigidity and precision.

VIDEO

Catalogs

No catalogs are available for this product.

See all of MAKINO Milling Machine‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Cutting CNC machining center

- Horizontal CNC machining center

- BT 40 CNC machining center

- EDM

- CNC machining center with pallet changer

- Compact CNC machining center

- Machining center for the automobile industry

- Turning-milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.