- Machine-tools

- Machining Center

- 5-axis machining center

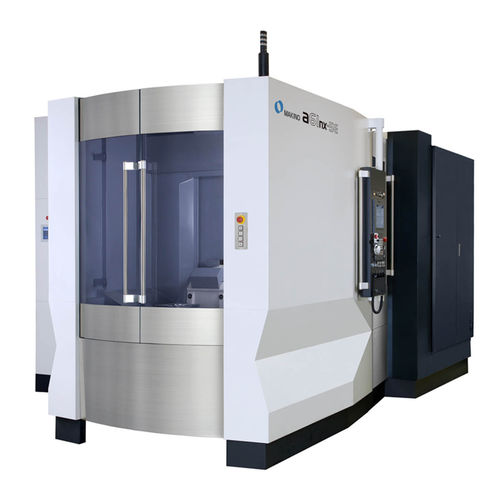

- MAKINO Milling Machine

5-axis CNC machining center a61nx-5Ehorizontalwith rotary tablefor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Structure

- with rotary table

- Machined material

- for aluminum

- Number of tool stations

- 60 tools

- Applications

- for the aerospace industry, for small parts production

- Other characteristics

- high-productivity, direct-drive, high-power, with pallet changer

- X travel

730 mm

(28.74 in)- Y travel

730 mm

(28.74 in)- Z travel

680 mm

(26.77 in)- Rotational speed

14,000 rpm, 24,000 rpm

(87,965 rad.min-1, 150,796 rad.min-1)- Power

80 kW

(108.77 hp)- Work feed X-axis

48,000 mm/min

(31 in/s)- Work feed Y-axis

48,000 mm/min

(31 in/s)- Work feed Z-axis

43,000 mm/min

(28 in/s)- Table load capacity

150 kg

(331 lb)- Tool weight (max)

12 kg

(26.5 lb)- Tool-changing time

0.9 s

Description

The a61nx-5E 5-Axis horizontal machining center offers the right-size solution for small aerospace parts production

The a61nx-5E five-axis horizontal machining center is built specifically for high-efficiency aluminum machining of small to mid-size, complex five-axis components and monolithic aerospace parts. Its design is based off of the widely successful nx-series machines

The a61nx-5E boosts productivity through the addition of twin direct-drive rotary axes for “one-and-done” efficiency. The a61nx-5E features an innovative automatic pallet changer design that directly loads the pallet into the 5th axis rotary table, while providing flat surface for ergonomic workpiece loading.

Spindle options for the a61nx-5E range from the standard 14,000 RPM high-power spindle, to a remarkable 24,000 RPM, 80kW (duty rated) spindle for aluminum machining in aerospace. This under-race-lubricated, core-cooled spindle is capable of metal removal rates of up to 300 cubic inches per minute in the machining of aluminum. The a61nx-5E brings the metal removal and productivity of Makino’s MAG machines to a smaller platform, allowing aerospace manufactures to “right size” their parts production.

VIDEO

Catalogs

No catalogs are available for this product.

See all of MAKINO Milling Machine‘s catalogsOther MAKINO Milling Machine products

5‑Axis Horizontal Machining Centers

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

- CNC machining center with pallet changer

- Horizontal CNC machining center

- BT 40 CNC machining center

- Compact CNC machining center

- EDM

- Machining center for the automobile industry

- Direct-drive CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.