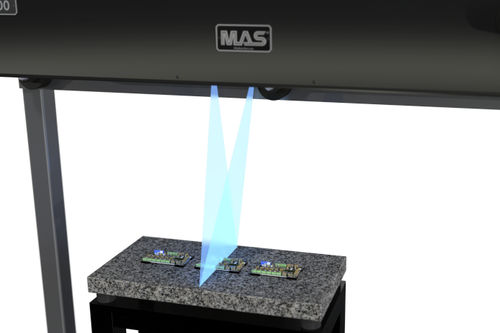

S1000: SINGLE-AXIS

LASER SCANNER

The S1000 is a single axis precision 3D laser scanning system capable of measurements and defect inspection of complex parts. Standard configuration uses a 3D laser profiler to traverse over a part while collecting 3D point cloud data. Data intervals may be as precise as up

to every 75 microns along Xand Y direction.

This 3D point cloud can be compared against a 3D CAD model of that same scanned part to analyze a variety of defects and measurement deviations. The $1000 system can be installed offline for manual use or in-line for integration with other equipment.

FEATURES

Included with every S1000 model is a PC loaded with innovative MAS

S-Series Analyzer software, a complete control panel and precision laser scanner.

Single-axis scanning

Servo motion with precision rails

Live temperature compensation is also available

BENEFITS

A cost-effective solution with quick cycle times! Our S1000 scanner and motion platform can be easily mounted overa work bench or it can be integrated with other equipment. Mount it over a conveyor for continuous scanning or add it to a robotic cell to extend the function of your exISting robot.

Easy integration

Precision scanning

Defect detection