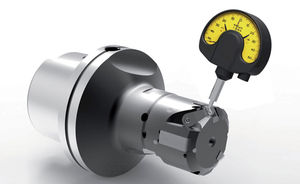

Indexing reamer FeedPlusblade

Add to favorites

Compare this product

Characteristics

- Type

- indexing

- Construction

- blade

- Diameter

Min.: 6 mm

(0.24 in)Max.: 40 mm

(1.57 in)

Description

Extremely high feeds thanks to extreme number of cutting edges

Precise roundness

Longer tool life thanks to more cutting edges

The most important measure for the performance of multi-bladed reamers is the number of blades. This is limited by the diameter of the tool and by the space required for the chip spaces. But what happens if we eliminate the chip spaces and can thus increase the number of blades? It is precisely this - certainly unconventional - technique that MAPAL has employed in the FeedPlus reamer. Whereas to date, for example, there was only space for eight blades on a 40 mm tool, the FeedPlus now has 16 blades on the same sized tool. Depending on the machining application, a wide range of different cutting materials are employed for these blades. The number of blades and the right choice of cutting material enable machining speeds to be achieved that were previously impossible during reaming.

Furthermore, through their support on the bore walls, the large number of blades ensures an outstanding circularity of the reamed bore. And the fact that the cutting work is now shared between more blades than to date also leads to a correspondingly increased tool life. Furthermore, the geometry in the area of the cutting lead and the coolant ensure reliable chip removal forward. No chip comes into contact with the reamed part of the bore.

VIDEO

Catalogs

No catalogs are available for this product.

See all of MAPAL‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- Insert milling tool

- End mill milling tool

- Coated milling cutter

- Cast iron milling tool

- Indexable cutting insert

- General purpose drill bit

- Cutting milling tool

- Hemispherical milling cutter

- Solid carbide milling tool

- Face milling tool

- Carbide drilling tool

- Roughing milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.