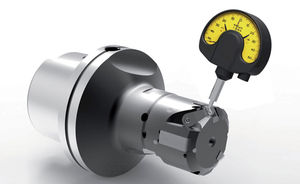

Solid milling cutter deburringwith cylindrical shankconical

Add to favorites

Compare this product

Characteristics

- Construction

- solid

- Type

- deburring

- Other characteristics

- with cylindrical shank, conical

Description

At a glance:

Higher precision

Better surface finish

50 % reduced axial forces compared with conventional countersinks

Less vibration at the tool

Time savings thanks to higher cutting speeds

No settling with bolted and riveted joints

Countersinks are standard products. They are produced in large quantities and are used in practically every machining process, because as the saying goes: No bore without a countersink. The design of countersinks, however, has barely changed over the past decades, if at all. Equipped with three blades, the tools have an equal pitch between the cutting edges. Large axial forces cause vibrations of the tool and result in a poor surface finish. Furthermore, the tools do not achieve long tool lives.

Catalogs

No catalogs are available for this product.

See all of MAPAL‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- Insert milling tool

- End mill milling tool

- Coated milling cutter

- Cast iron milling tool

- Indexable cutting insert

- General purpose drill bit

- Cutting milling tool

- Hemispherical milling cutter

- Solid carbide milling tool

- Face milling tool

- Carbide drilling tool

- Roughing milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.