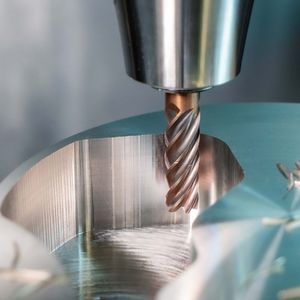

Indexing reamer WP/MN 2223 series2-lip

Add to favorites

Compare this product

Characteristics

- Type

- indexing

- Construction

- 2-lip

- Diameter

Max.: 40.29 mm

(1.59 in)Min.: 14.3 mm

(0.56 in)

Description

With the twin-bladed reamers higher cutting speeds and feed rates can be applied compared to single-bladed guide pad reamers.

The cutting blades are radially and axially differently set. Dividing the cutting depth in a premachining and finishing cut with only a few hundrets of a millimeter stock removal the surface finishing and structure is unique and lonng tool life is the result even in difficult materials.

Based on this principle MAPAL also offers multi-bladed tools as for example tools with 4 + 2 blades. These tools have 4 premachining and 2 finishing blades and run with even higher feed rates.

Catalogs

No catalogs are available for this product.

See all of MAPAL‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- Insert milling tool

- End mill milling tool

- Coated milling cutter

- Cast iron milling tool

- Indexable cutting insert

- General purpose drill bit

- Cutting milling tool

- Hemispherical milling cutter

- Solid carbide milling tool

- Face milling tool

- Carbide drilling tool

- Roughing milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.